30

/year

Deeply cultivating the mold industry for more than 30 years

Deep ploughing mold industry more than 30 years

30

/year

Deeply cultivating the mold industry for more than 30 years

Deep ploughing mold industry more than 30 years

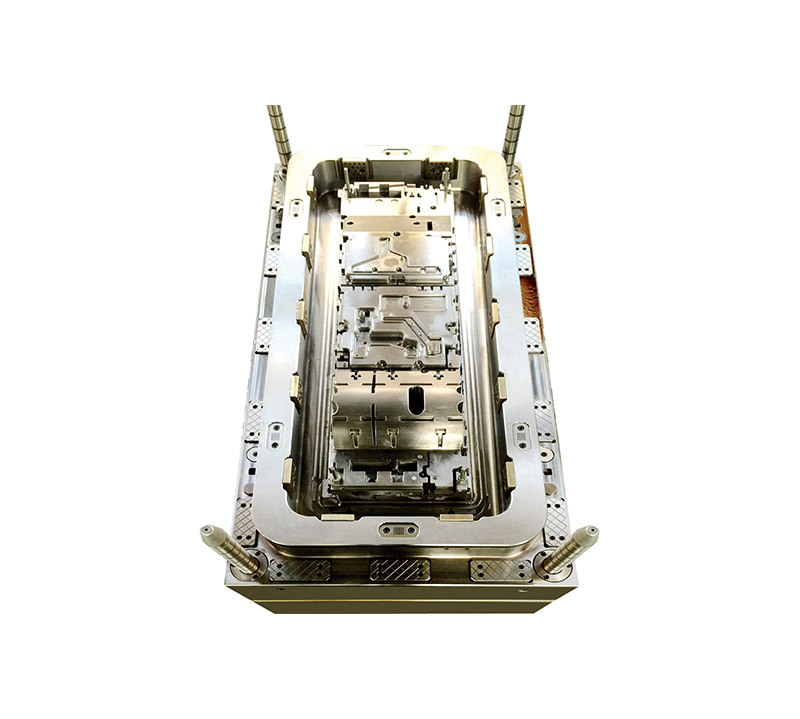

PRODUCTS

More precise, faster, more efficient, your side of the mold customization experts

PRODUCTS

More precise, faster, more efficient, your side of the mold customization experts

Customized molds

according to user requirements

Customized mold according to user requirements

Learn MoreFeatured products

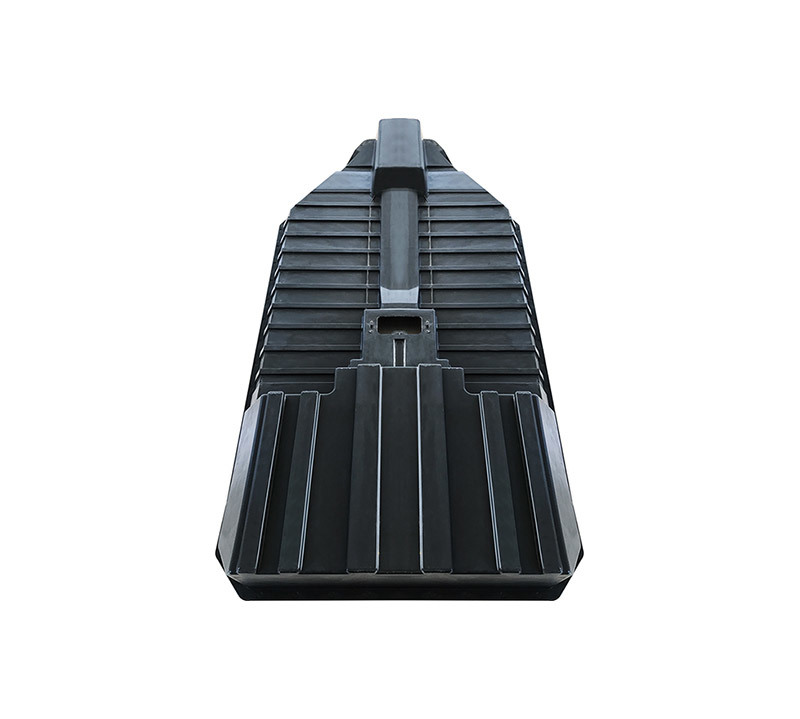

Committed to SMC, BMC, GMT, LFT-D, HP-RTM, PCM and other composite material mold research and development and manufacturing

Featured products

why choose us

Enterprise culture

Hua Cheng's Values-Honesty and Trustworthiness Based on Fundamental

Work style ---- pragmatic and enterprising and efficient development

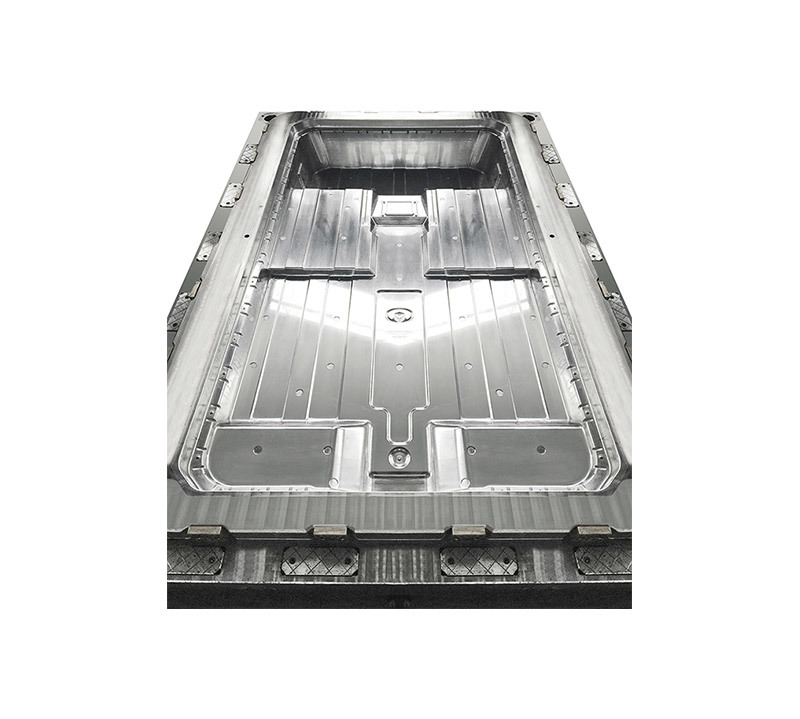

Processing equipment

It has many imported large-scale high-speed gantry processing equipment, frame-type 4000 T.2000T and 800T special liquid jade machine wire cutting, etc.

Our team

The company has the pursuit of research and development design department, strict quality control department and project quality control department.

Enterprise honor

the company passed the IS09001:2015 quality system certification, ISO14001:2015 environmental system certification...

Taizhou Huacheng Mould Co., Ltd

SINCE 1994

Taizhou Huacheng Mould Co., Ltd., founded in 1994, is located in Tiantai Baihe Industrial Park, Taizhou City, Zhejiang Province, the hometown of moulds, with a history of more than 30 years. It is a vice-chairman unit of Shanghai Mould Technology Association and a director unit of China Composite Material Industry Association. The company covers an area of more than 20000 square meters, the existing professional and technical personnel more than 70 people. In the early days of its establishment, the company mainly manufactured all kinds of plastic moulds. Since 2003, it has been transforming to focus...

Learn More

Committed to the research and development and manufacturing of SMC, BMC, GMT, LFT-D, HP-RTM, PCM and other composite molds. At present, CAD/CAM technology has been adopted in mold making. It has a pursuing research and development design department, a strict quality control department and a project quality control department, as well as many imported large-scale high-speed gantry processing equipment. The design field...