[Focusing on High-Quality Development] Taizhou Huacheng Mould Co., Ltd.: Accelerating the breakthrough of intelligent mould manufacturing through "Smart Manufacturing + Export".

Release time:

2025-08-11

In Taizhou, Zhejiang Province, a mold manufacturing company driven by integrity and founded on quality is quietly emerging.

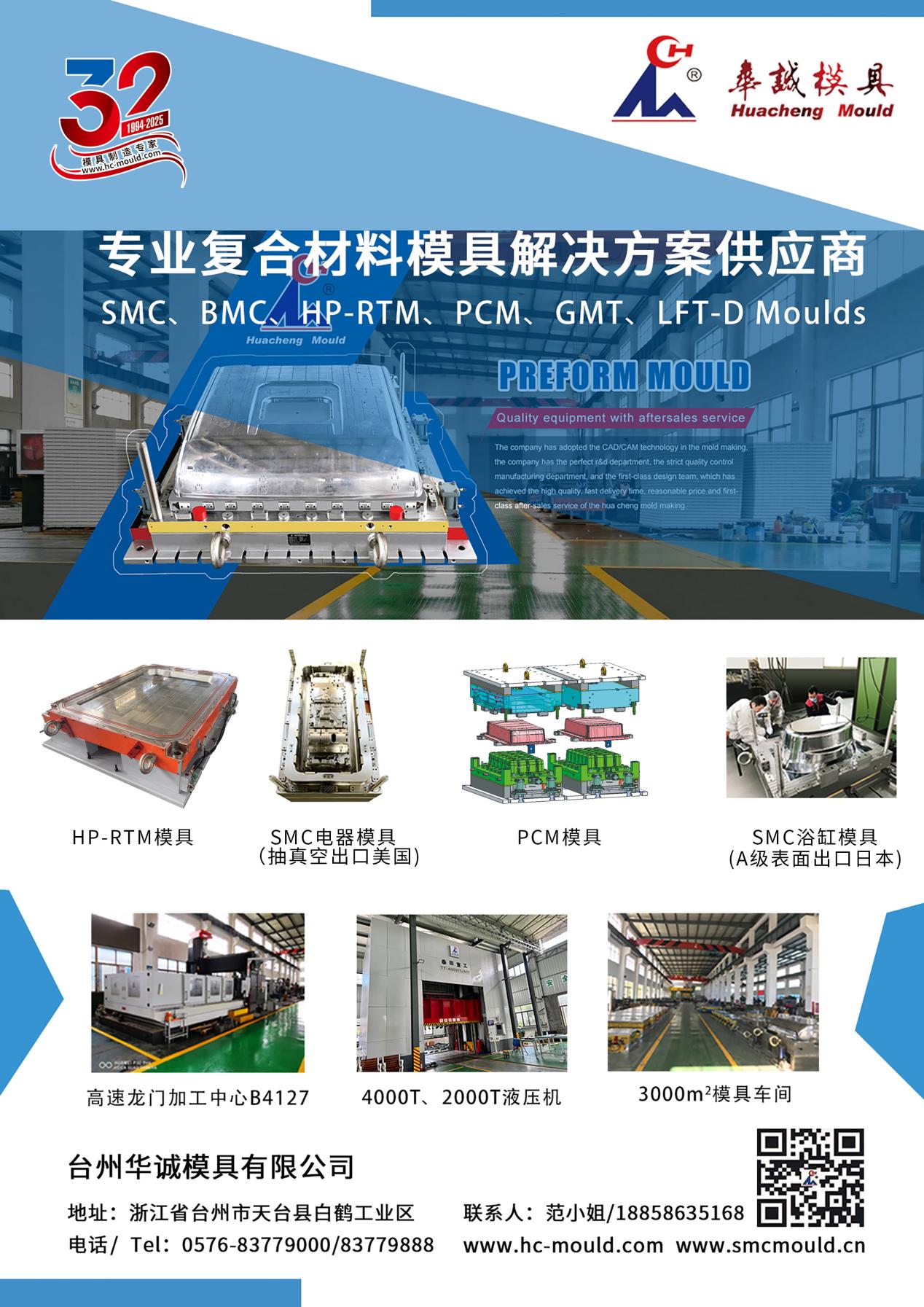

In Taizhou, Zhejiang Province, a mold manufacturing enterprise driven by integrity and founded on quality is quietly rising. Taizhou Huacheng Mold Co., Ltd. (hereinafter referred to as "Huacheng Mold") is located in Tiantai, near the "Hometown of Chinese Molds," with convenient transportation. Established in 1994, it focuses on the research and manufacturing of composite material molds such as SMC, BMC, GMT, PCM, LFT-D, HP-RTM, and has been deeply engaged in the mold industry for over thirty years. It now holds a significant position in the local mold industry and has become a benchmark enterprise promoting green and efficient development in the regional mold sector.

Dual-driven by intelligent manufacturing and export, forging industry benchmark strength

Intelligent transformation is an important driving force for achieving connotative development of enterprises and industries and enhancing core industrial competitiveness. In recent years, Huacheng Mold has taken a series of effective measures to actively explore a distinctive path for high-quality development in the mold industry, helping the company accelerate breakthroughs toward high-end, intelligent, and green development. It has established an intelligent production base equipped with more than 20 large CNC machines and 4 thousand-ton high-precision hydraulic presses.

Currently, about 50% of molds are exported to Europe, America, and Southeast Asian countries and regions. The company has been awarded National High-tech Enterprise, Zhejiang Province Innovative Enterprise, Taizhou High-tech Enterprise, Tiantai Top 50 Enterprises, and has been recognized for over ten consecutive years by the local government as a "Contract-abiding and Trustworthy Enterprise" with a credit rating of AAA.

Through ISO's three major international system certifications (quality, environment, occupational health and safety), the company continuously delivers high value-added products with a green intelligent manufacturing concept.

Technical Breakthrough: Digital Empowerment for Precision Intelligent Manufacturing

Huacheng Mold takes intelligent CNC programming as its core competitiveness. Mold making uses CAD/CAM technology and relies on advanced equipment such as gantry machining centers, high-speed milling, wire cutting machines, and EDM machines to provide one-stop services from design and R&D to mass production and delivery. This precisely meets customers' customized needs, reducing delivery cycles by 20% and helping customers seize market opportunities.

Accelerating Breakthrough: Facing Challenges Head-on

From the perspectives of technological innovation, market prospects, and consumption potential, the mold industry remains one of Taizhou's important pillar industries and will continue to play a vital role in industrial restructuring. Huacheng Mold will face challenges head-on, relying on intelligent CNC programming and advanced mold-making technology to accelerate the breakthrough from "manufacturing" to "intelligent manufacturing."

Strict Quality Control: Three Lines of Defense to Achieve a "Zero Defect" Commitment

Huacheng Mold implements the "Three No's Principle" in quality management throughout the entire mold manufacturing process, building a quality assurance system:

➢ Commitment One: No acceptance of non-conforming products

Before production and processing, employees inspect the products passed from the previous process according to regulations. If any issues are found, they have the right to refuse acceptance and promptly report back to the previous process. The previous process personnel must immediately stop processing, investigate the cause, and take measures to ensure quality problems are detected and corrected in time, preventing waste caused by further processing of non-conforming products.

➢ Commitment Two: No manufacturing of non-conforming products

After accepting qualified products from the previous process, employees strictly follow operational standards during processing to ensure quality. They fully prepare for pre-operation inspections and confirmations; continuously monitor the process status to avoid abnormalities. Adequate preparation and confirmation during the process are key to preventing the production of non-conforming products. Only by not producing can non-conforming products be prevented from flowing out.

➢ Commitment Three: No outflow of non-conforming products

After completing processing in the current process, employees must inspect and confirm product quality. If defective products are found, they must immediately stop the machine, isolate the defective products in the current process, and take effective corrective measures promptly. This ensures no errors occur in the current process.

Product Matrix: Deep Empowerment of High-end Manufacturing Scenarios

Huacheng Mold focuses on innovative applications of polymer composite materials, with core products covering many fields:

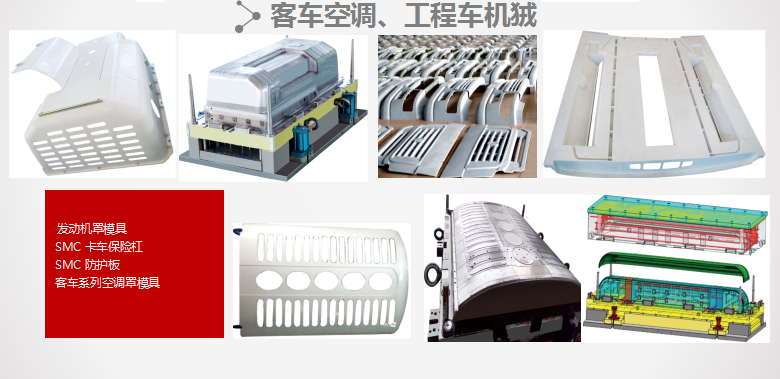

➢ Field One: Molds for commercial vehicles, passenger cars, tractors, and other parts

Some molds are supplied to well-known domestic and foreign manufacturers, and some are exported to Europe, America, Southeast Asia, and other countries.

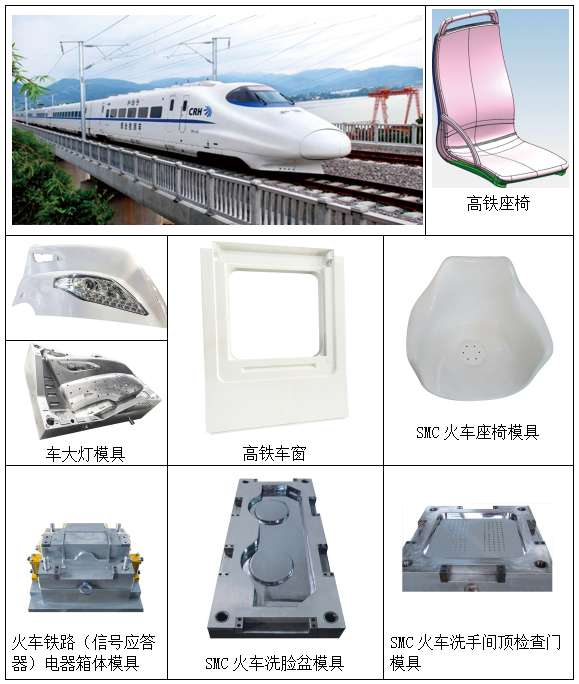

➢ Field Two: High-speed rail interior accessory molds

Interior products such as windows, seats, washbasins, and other series, most of which are exported abroad.

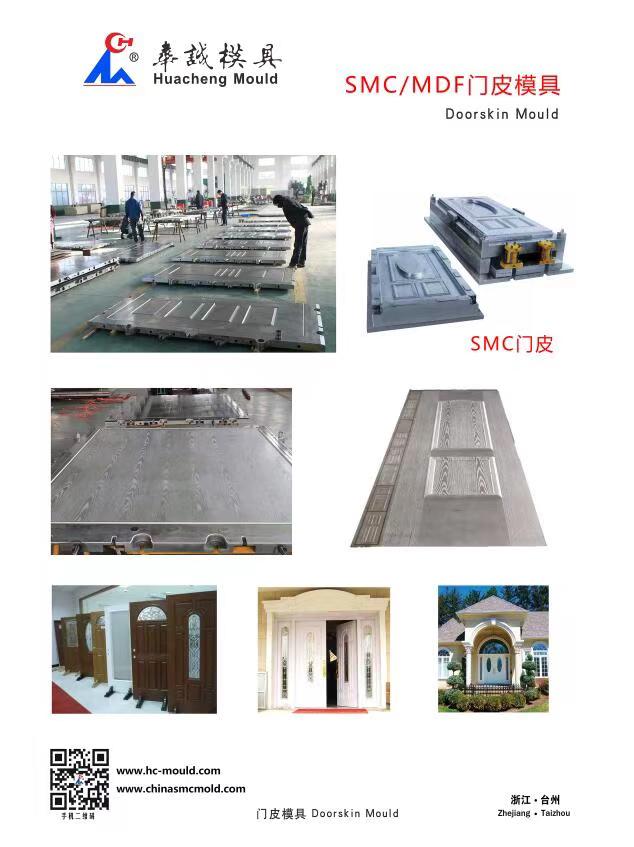

➢ Field Three: Door skin molds

Door skin molds exported to Thailand, Malaysia, and other countries.

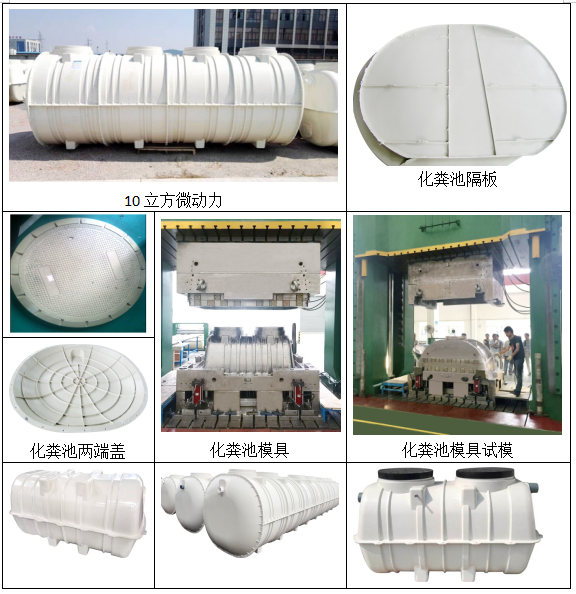

➢ Field Four: Septic tank molds

Septic tank molds, through standardized mold production processes, greatly shorten the production cycle of septic tanks, reduce production costs, and also minimize material waste.

➢ Field Five: Molds for power and electrical appliances

Including molds for power grid terminal shells (electric meter boxes), battery covers, electrical cabinets, electric irons, water tank panels, lampshades, and other products.

➢ Also involved: molds for seat series, motorboats, sports goods, bathroom and kitchen, medical equipment, and other fields.

Technology is the primary productive force. Huacheng Mold's R&D and design embody the company's integrated work of absorption, introduction, innovation, design, implementation, and results in product operations. Through creative thinking, Huacheng Mold precisely positions and designs products to create greater value for enterprises. With years of experience, solid technology, and quality service, it has earned the trust and praise of many customers.

Future Vision: Dedicated Craftsmanship, Innovating with Intelligence

Standing at the intersection of the "dual carbon" strategy and the digital wave, Huacheng Mold continues to increase R&D investment, tackling cutting-edge technologies such as ultra-large integrated molds and low-carbon forming processes. In the future, the company will take the "smart factory" upgrade as an opportunity to promote the industry toward deeper green and digital development, injecting strong momentum into the high-quality development of Made in China!

Taizhou Huacheng Mold Co., Ltd. — Reshaping mold value with technology, defining industry height with quality. Sincerely inviting global partners to join hands and co-create a new future of intelligent manufacturing!

Let's start cooperation

In today's manufacturing industry facing profound adjustments, Huacheng Mould breaks through obstacles with integrity, wins customer trust with quality, and creates product value through service, writing epic stories of private enterprises' struggles. Its story is not only about technological and business success but also reflects the era's trend of China's manufacturing transforming into intelligent manufacturing. In the future, with the widespread application of polymer composite materials, Huacheng Mould will surely inject more vitality into urban renewal and rural revitalization, leaving a significant mark in the manufacturing history of China and even the world.

Adhering to Huacheng, Unwavering Craftsmanship

Taizhou Huacheng Mould Co., Ltd., established in 1994, is located in Baihe Industrial Park, Tiantai, Taizhou City, Zhejiang Province, known as the hometown of moulds, with over thirty years of mould-making history. It is a vice-chairman unit of the Shanghai Mould Technology Association and a council member of the China Composite Materials Industry Association. The company covers more than 20,000 square meters and currently has more than 70 professional technical staff. It focuses on the research and manufacturing of composite material moulds such as SMC, BMC, GMT, LFT-D, HP-RTM, PCM, and currently uses CAD/CAM technology in mould making.

The company has a perfection-seeking R&D design department, strict quality control and project quality management departments, as well as multiple imported large high-speed gantry machining equipment. The moulds have advantages of high quality, fast delivery, and reasonable prices, providing global customers with high-quality, cost-effective products and excellent after-sales service, earning unanimous praise from new and old users. It is a professional manufacturer in the composite material mould industry, involved in aerospace, high-speed rail and subway, automotive, electrical appliances, building materials, sports goods, integrated bathroom, water treatment series, and other fields. The mould technology has reached international standards. It has also passed ISO9001:2015 quality management system certification, ISO14001:2015 environmental management system certification, ISO45001:2018 occupational health and safety management system certification; awarded National High-tech Enterprise, Zhejiang Province Innovative Enterprise, Taizhou High-tech Enterprise, Tiantai Top 50 Enterprises, and has been rated as a "Contract-abiding and Trustworthy Unit" locally for more than ten consecutive years. Its credit rating is AAA, making it a leading enterprise in the local mould industry.

Company website: www.hc-mould.com

Contact phone: Fan Qionglin 18858635168

Address: Baihe Industrial Zone, Tiantai County, Taizhou City, Zhejiang Province

Related News

![First Batch of Innovation Award Winners | [Taizhou Huacheng Mould Co., Ltd.] Receives the 2025 11th IALTA (China) Automotive Lightweighting and Green Technology Innovation Award First Batch of Innovation Award Winners | [Taizhou Huacheng Mould Co., Ltd.] Receives the 2025 11th IALTA (China) Automotive Lightweighting and Green Technology Innovation Award](/npublic/img/s.png)