"Prepreg" — the "material backbone" of aerospace and new-energy vehicles

Release time:

2025-09-29

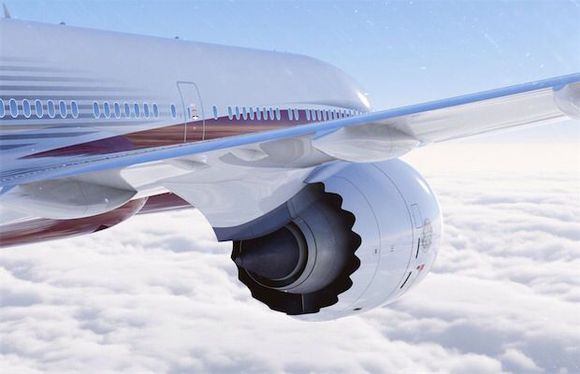

Cars need to be lighter, large aircraft require lightweight designs, and wind turbine blades must be durable.

Cars need to be lighter, large aircraft require lightweight designs, and wind turbine blades must be incredibly durable… Today, whether it’s high-end manufacturing or the new energy sector, everyone is calling for "new materials." But here’s the thing—those advanced composite materials that can withstand extreme altitudes and endure harsh temperature fluctuations all rely on one "critical semi-finished product"— Prepreg 。

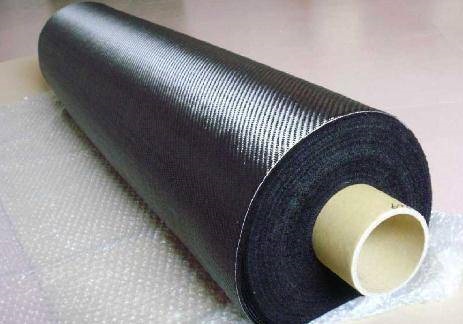

It’s called a "semi-finished product" because it’s not ready for direct use—instead, it’s crafted by soaking fibers (such as carbon fiber or glass fiber) in resin, creating a "composite assembly" that essentially wraps the fibers in a functional "protective layer." Only then is it further processed into various components. Today, let’s dive deep into this "unsung hero" hidden within composite materials.

First, let’s understand: What exactly is prepreg? And what are its main categories?

Simply put, prepreg is essentially a combination of "fibers + resin"—a material created by evenly saturating continuous fibers (such as carbon fiber or aramid) or fabrics with resin under tightly controlled conditions. These materials come in the form of rolls or sheets, and they serve as the foundational starting point for manufacturing everything from aircraft components to automotive frames.

It may seem like there are many categories at first, but actually, when sorted by "ingredients" and "form," you can quickly get things straightened out:

1. Classified by Resin

For example, epoxy prepregs, polyamide prepregs, phenolic prepregs—these resins act like "adhesive + functional additives," determining the final material's temperature resistance and corrosion-proof properties.

2. Classified by Reinforced Fibers

The most common ones are carbon fiber prepregs (lightweight and strong), glass fiber prepregs (cost-effective), as well as aramid prepregs (impact-resistant) and basalt fiber prepregs (resistant to extreme temperatures).

3. Classified by Fiber Morphology

Some are unidirectional fibers (with fibers aligned in one direction for greater strength), others are fabric prepregs (similar to cloth, ideal for complex shapes), and there are also chopped fiber prepregs (perfect for crafting small components).

No matter how it's divided, the core idea remains: "Fibers provide load-bearing strength, while resins handle adhesion and impart functionality." Only when these two components are perfectly matched can you create reliable composite materials.

Key difference: What exactly is the gap between thermoplastic and thermoset prepregs?

When it comes to prepregs, you can't avoid talking about "thermoplastic" and "thermoset"—these two have quite different applications. Let's get straight to the point:

1. Thermoplastic prepreg: "Can be stored at room temperature—softens when heated"

It uses thermoplastic resins (such as PP, PEEK, and others), which have particularly distinct characteristics:

Ultra-stable at room temperature: No need to refrigerate—there’s no “shelf life,” either. Just take it out and use it right away; it’s convenient for both storage and transportation.

Flexible processing: When heated to a certain temperature, it becomes soft and easily shaped; once cooled, it hardens again. And if it gets damaged, simply reheating it can restore its original form—though in high-end applications, repairs are rarely necessary. Still, this property makes it incredibly practical. Nowadays, many automotive components and everyday household items made from composite materials rely on this material.

2. Thermoset prepreg: "Must pass the B-stage and remain dimensionally stable after curing."

It is currently the more widely used type, especially in high-end fields like aerospace, where the core resin is epoxy resin—and the process tends to be a bit more complex.

The first step is to reach "Stage B": Initially, the resin is liquid. After being浸 coated onto the fibers, it must first undergo "partial curing"—transforming from a liquid into a slightly sticky solid, but not yet fully hardened. This is precisely "Stage B."

The second step requires "complete curing": When it’s time to use, you need to apply heat and pressure to temporarily revert the resin from its B-stage back into a liquid state (filling the gaps between the fibers), followed by thorough cross-linking and hardening, transforming it into a rigid structural component that will no longer soften even when reheated. Although storage does require careful attention—some types even need refrigeration—the cured material exhibits exceptionally stable performance, resisting both high temperatures and tensile forces. That’s why it’s widely used in aircraft fuselages and missile components.

4 Processing Techniques: How Do Different Prepregs Become "Finished Products"?

Prepreg is merely a "semi-finished product"—to transform it into the aircraft wings or wind turbine blades we see, it still requires four mainstream processing techniques, each excelling in its own unique area.

1. Autoclave Molding: It’s ideal for manufacturing "complex large components"—simply lay the prepreg material onto the mold according to its shape, cover it with a vacuum bag, and then place everything into an autoclave. While heating and applying pressure simultaneously, the resin cures completely. This process is essential for crafting intricately shaped aircraft components and critical sections of massive wind turbine blades—resulting in parts that boast exceptionally smooth surfaces on one side.

2. Vacuum Curing Furnace Molding: It follows the same principle as "cost reduction and larger-scale production" as with an autoclave, but the equipment is much larger in size—capable of accommodating multiple medium- to small-sized parts at once, or even manufacturing components that exceed the dimensions of those produced by an autoclave. As a result, the cost per individual product can be significantly reduced. Today, this process is widely used for many high-speed rail components and large-scale composite material structures.

3. High-Temperature Molding: Suitable for "mass-producing small parts," first cut the prepreg material into the desired shapes, neatly stack them into the mold, and then directly heat and press to form the final product. This process is simple, fast, and ideal for the high-volume production of small components used in automobiles, fishing gear, and even racing boat parts.

4. Induction Heating Molding: Suitable for "producing large, high-precision components," it resembles high-temperature mold pressing—but here, the heat source directly contacts the mold, enabling faster heating and eliminating size limitations of conventional press equipment. This allows for the creation of exceptionally large yet highly accurate parts, such as the outer shells of massive spacecraft or the advanced chassis of premium automobiles.

The "battlefield" of prepreg materials: From large aircraft to hydrogen-powered vehicles, none can do without it.

Nowadays, the application of prepregs has long since permeated every aspect of high-end manufacturing, particularly in these several fields, where demand is growing especially rapidly:

1. Aerospace: Domestic large aircraft and next-generation vehicles are increasingly demanding materials that are both "lightweight and high-strength," making thermoset prepregs—especially carbon-fiber epoxy prepregs—their core material. In the future, these materials are likely to face a growing supply shortage.

2. New Energy Sector: Wind turbine blades rely on carbon fiber prepregs to withstand strong winds, while hydrogen-powered vehicles' onboard composite gas cylinders and photovoltaic systems' polycrystalline silicon crucibles also depend on this material—making it a "stabilizing force" that drives demand for carbon fiber.

3. Automotive Sector: Whether it's a gasoline-powered vehicle or a new-energy car, both aim to reduce weight and improve fuel efficiency. Carbon fiber prepreg materials produce车身 and传动 shafts that are not only lightweight but also incredibly strong—qualities that are now increasingly adopted in high-end models by automakers both at home and abroad.

Future Trends: Where Are Prepregs Headed? 3 Key Directions

As manufacturing becomes increasingly advanced, the requirements for prepregs are also growing stricter. Looking ahead, development will primarily focus on these three directions:

1. More environmentally friendly "hot-melt prepreg": Currently, the mainstream "solution impregnation method" involves volatile solvents, making it environmentally unfriendly and leading to poor control over resin content. In the future, the "hot-melt adhesive film method" will be used more widely—first, the resin is processed into an adhesive film, which is then combined with fibers. This approach eliminates solvent-related pollution, ensures precise resin content, and better aligns with the demands of green manufacturing.

2. "Long-term Storage at Room Temperature": Nowadays, many thermoset prepregs need refrigeration, which drives up costs. In the future, we'll develop resin systems that can be stored long-term at room temperature—eliminating the need for cold storage facilities or modifications to molding equipment—and significantly reducing expenses.

3. Performance must "reach a whole new level": Aircraft need to be "lighter, more stealthy, and more resistant to ablation," while electronic devices demand "higher frequencies and greater reliability." This, in turn, calls for prepregs that can withstand higher temperatures, exhibit superior mechanical strength, and offer enhanced dielectric properties—such as the prepregs used in copper-clad laminates, which must endure elevated heat levels to ensure stable signal transmission.

After all, prepreg materials are essentially the "skeleton" of composite materials—only with a strong enough framework can we ensure the safety of large aircraft, the efficiency of next-generation electric vehicles, and the durability of wind turbine blades. Currently, China's prepreg industry is still growing. As breakthroughs in new material technologies continue to emerge, the future holds not only the potential to overcome foreign technological barriers but also to provide a solid "material foundation" for even more advanced manufacturing sectors.

Related News

![First Batch of Innovation Award Winners | [Taizhou Huacheng Mould Co., Ltd.] Receives the 2025 11th IALTA (China) Automotive Lightweighting and Green Technology Innovation Award First Batch of Innovation Award Winners | [Taizhou Huacheng Mould Co., Ltd.] Receives the 2025 11th IALTA (China) Automotive Lightweighting and Green Technology Innovation Award](/npublic/img/s.png)