Understanding the molding, applications, and advantages of thermoplastic fiber-reinforced composites

Release time:

2025-07-30

Composite materials are materials composed of two or more different physical properties or different chemical substances combined to form a multiphase, three-dimensional structure with distinct interfaces between phases and special properties. They mainly consist of reinforcement materials and matrix materials, with the most notable feature being that the performance of the composite material exceeds that of the individual constituent materials.

Composite materials are materials composed of two or more different physical properties or different chemical substances through compounding, forming multiphase, three-dimensional bonding with distinct interfaces between phases, and possessing special properties. They mainly consist of reinforcement materials and matrix materials, with the greatest feature being that the performance of the composite material is superior to that of the individual constituent materials.

Fiber-reinforced thermoplastic composites are an important branch of composite materials, using glass fiber (GF), carbon fiber (CF), aramid fiber (AF), and other fiber materials to reinforce various thermoplastic resins. Abroad, they are called FRTP (Fiber Reinforced ThermoPlastics). Advanced fiber-reinforced thermoplastic composites have excellent properties such as toughness, corrosion resistance, high fatigue resistance, simple molding processes with short cycles, high material utilization (no waste), and no need for low-temperature storage, making them a research hotspot in the materials industry.

Typical performance advantages of FRTP

Thermoplastic composite FRTP has a history of mature applications spanning several decades. Compared with thermosetting composites such as phenolic resin, urea-formaldehyde resin, epoxy resin, and polyurethane, thermoplastic composites have some special properties:

◆ Low density, high strength: The density of FRTP is 1.1 to 1.6 g/cm 3 , only 1/5 to 1/7 that of steel, and 1/3 to 1/4 lighter than thermosetting fiberglass, enabling higher mechanical strength and application grade per unit mass.

◆ High degree of design freedom for performance: The physical, chemical, and mechanical properties of FRTP are designed by reasonably selecting raw material types, ratios, processing methods, fiber content, and layup methods. Since the types of matrix materials are much more numerous than thermosetting composites, mainly including polyether ketone ketone (PEKK), polyether ether ketone (PEEK), polyphenylene sulfide (PPS), nylon (PA), polyetherimide (PEI), etc., the freedom in material selection and design is much greater.

◆ Thermal performance: The typical use temperature of general plastics is 50 to 100°C. After reinforcement with glass fiber, it can be increased to above 100°C. The heat distortion temperature of PA6 is 65°C; after 30% glass fiber reinforcement, it can be increased to 190°C. PEEK has a heat resistance of 220°C; after 30% glass fiber reinforcement, the use temperature can be increased to 310°C, which thermosetting composites cannot achieve.

◆ Chemical corrosion resistance: Mainly determined by the properties of the matrix material. There are many types of thermoplastic resins, each with its own corrosion resistance characteristics. Therefore, the matrix resin can be optimized according to the usage environment and medium conditions of the composite material, generally meeting usage requirements. FRTP also has better water resistance than thermosetting composites.

◆ Electrical properties: FRTP generally has good dielectric properties, does not reflect radio waves, and has good microwave transmission performance. Since FRTP has a lower water absorption rate than thermosetting fiberglass, its electrical properties are superior. Adding conductive materials to FRTP can improve its conductivity and prevent static electricity.

◆ Waste can be recycled: FRTP can be reprocessed and molded, and waste and scraps can be recycled without significant changes in physical and mechanical properties, avoiding environmental pollution and well meeting the current global environmental protection requirements for the materials industry.

Classification of FRTP

There are many types of FRTP, and the industry is filled with numerous technical English abbreviations, which can be confusing. According to the fiber retention size (L) in the product, it can be divided into: short fiber reinforced thermoplastic (SFRT, L < 1.0 mm), long fiber reinforced thermoplastic (LFT or LFRT, generally L > 10 mm), and continuous fiber reinforced thermoplastic composite plastic (CFRT, generally continuous fibers not cut).

Compared with SFRT, LFT has characteristics such as low density, high specific strength, high specific modulus, and strong impact resistance, suitable for harsh application conditions. This is one of the main reasons LFT is favored by downstream application industries. The more commonly used LFT materials can be roughly categorized into three types: glass mat reinforced thermoplastics GMT (Glass Mat Reinforced Thermoplastics), long-fiber reinforced thermoplastic granules LFT-G (Long-Fiber Reinforced Thermoplastic Granules), and long-fiber reinforced thermoplastic direct online molding LFT-D (Long-Fiber Reinforced Thermoplastic Direct).

CFRT is recyclable, has high specific strength and specific stiffness, good corrosion resistance, impact resistance, heat resistance, low cost, and design flexibility. It has huge application potential in automotive lightweight design and can replace some metal materials and high-end polymer materials.

Applications of FRTP

With the emergence of rigid, heat-resistant, and medium-resistant aromatic thermoplastic resin matrices (such as PEEK, PPS), and the development of high-performance fibers such as carbon fiber, aramid fiber, and silicon carbide fiber with high strength, high modulus, high temperature resistance, and corrosion resistance, advanced FRTP is increasingly applied in various industrial fields such as rail transit, automotive, aerospace, home appliances, and electric power.

◆ Aerospace

FRTP has high stiffness, low processing cost, and reprocessing capability, with good flame retardancy, low smoke, and non-toxic properties. The curing cycle can be measured in minutes. These inherent properties make it an ideal material for lightweight, low-cost aerospace structures.

In aerospace structural components, FRTP is mainly used in floors, leading edges, control surfaces, and tail parts, which are relatively simple secondary load-bearing components. The Airbus A380, Airbus A350, Gulfstream G650 business jet, and AgustaWestland AW169 helicopter are major users of thermoplastic structural components. The most important FRTP structural component on the Airbus A380 is the glass fiber/PPS material fixed leading edge of the wing. The FRTP on the Airbus A350 fuselage is mainly distributed on movable wing beams and ribs as well as fuselage joints. The Gulfstream G650 business jet is a milestone in FRTP application; its pressure bulkhead ribs use carbon fiber/PEI material, while the rudder and elevator use carbon fiber/PPS material (see Figure 1).

◆ Automotive

Developing low-cost, short-cycle, and high-quality composite material technologies has become one of the key factors driving automotive lightweighting. Many domestic car manufacturers have already cooperated with injection molding equipment companies that possess advanced composite material technologies. Applications in passenger cars include: seats and their frames, window guides, door inner panels, bumper brackets, engine hoods, front brackets, foot pedals, instrument panel frames, deflectors, vehicle floor panels, spare tire boxes, battery brackets, and automotive intake manifolds. Domestic car models such as Passat, POLO, Bora, Audi A6, Golf, Buick Excelle, and Buick GL8 business vehicles have adopted a large number of high-performance FRTP parts, most of which use GMT or LFT (Figure 2).

In the application for box trucks, the main material is PP honeycomb composite panels, replacing the current steel frame outer aluminum alloy small corrugated panels and steel corrugated panels in box trucks.

◆ Rail Transit

According to load-bearing characteristics, they can be roughly divided into two categories: composite material main load-bearing parts and composite material non-main load-bearing parts. Composite material main load-bearing parts mainly refer to large load-bearing components of trains such as train bodies, driver cabins, and bogie frames. These are key to replacing traditional materials with composites to achieve vehicle lightweighting. Composite material non-main load-bearing parts can be divided into non-main load-bearing parts (such as car bodies, floors, and seats) and auxiliary parts (such as washrooms, toilets, and water tanks).

Common FRTP Molding Processes

The key process step in transforming raw materials into FRTP structural products is the molding process, which is the foundation and condition for the industry's development. With the expansion of composite material application fields, the composite material industry has developed rapidly. Some molding processes have been perfected, and new molding methods continue to emerge. Currently, there are more than 20 FRTP molding methods successfully used in industrial production. Below are brief introductions to several commonly used molding methods.

◆ Injection Molding

Injection molding is the main production method for FRTP, with a long history and wide application. Its advantages include short molding cycles, minimal energy consumption, high product precision, the ability to mold complex and insert-bearing products in one shot, and the capability to produce multiple products per mold, resulting in high production efficiency. The disadvantages are higher requirements for producing fiber-reinforced composites and mold quality. According to current technological development, the maximum product weight for injection molding is 5kg, and the minimum is 1g. This method is mainly used to produce various mechanical parts, construction products, household appliance shells, electrical materials, and vehicle parts.

FTRP molding technology has been mass-produced in automotive structural components. Currently, several injection molding equipment suppliers, such as ENGEL and KraussMaffei abroad, and Bole Plastic Machinery domestically, are at the forefront of this technology.

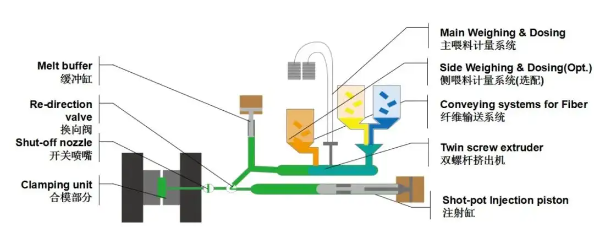

Bole Plastic Machinery's long fiber reinforced composite direct injection molding (online compounding injection molding) LFT-D-IM combines the continuous production of extruders with the intermittent production of injection molding machines. The material mixed by twin-screw compounding is directly injected into the mold, achieving multiple processes and multiple materials in one molding, reducing energy consumption, improving efficiency, reducing material thermal degradation, and enhancing product performance. This technology is widely applicable in automotive, home appliances, new energy, rail transit, aerospace, and consumer electronics fields (Figure 3).

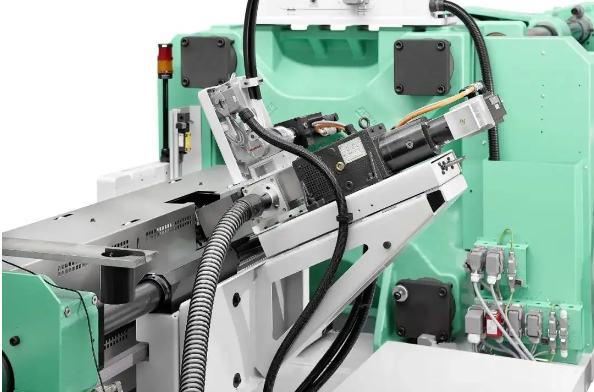

At Chinaplas 2022, ARBURG will showcase a large hydraulic injection molding machine ALLROUNDER 820 S, optimized for fiber direct compounding (FDC), featuring a clamping force of 4000kN and an injection unit of 3200, equipped with a 70mm special screw for processing long glass fibers. FDC is a lightweighting process that feeds fibers up to 50mm directly into the molten plastic through a side feeder next to the injection unit. It is characterized by high material availability and cost reduction of up to 40% compared to special long fiber pellets. Products produced by the FDC process represent an innovative technology in the plastics processing industry, especially in automotive manufacturing and aerospace, where glass fiber length can be customized to achieve desired physical properties (Figure 4).

◆ Extrusion Molding

Extrusion molding is one of the widely used processes in FRTP product manufacturing. Its main features are continuous production, high efficiency, simple equipment, and easy-to-master technology. Extrusion molding is mainly used to produce pipes, rods, plates, and profiles with special cross-sections.

◆ Winding Molding

The winding molding process for FRTP involves preheating continuous fibers impregnated with resin (prepreg yarn), winding them onto a mandrel, continuously heating to melt the resin, and then applying pressure to bond the prepreg layers into a whole. After layer-by-layer bonding and cooling, the corresponding component product is obtained. This method is suitable for manufacturing cylindrical and spherical products, with good reproducibility and stable performance.

◆ Pultrusion Molding

Pultrusion molding (pulling extrusion, pultrusion) is a process where prepreg yarns are pulled through an extrusion die under traction force to form and cure, continuously producing hollow and shaped products of unlimited length.

When long and thin door and window profiles or concrete reinforcements are needed, pultrusion technology comes into play. The fibers in pultruded profiles are completely aligned with the load direction, making the finished products excellent in material and weight. In 2017, KraussMaffei first launched the turnkey pultrusion system - iPul (Figure 5), which has continuously generated strong interest in the construction, wind energy, and automotive industries. The iPul system integrates resin injection and profile pulling lines, enabling full process control of glass fiber and carbon fiber pultrusion molding, helping composite profile production improve efficiency and reduce costs. The iPul system includes molds, metering machines, and various accessories, achieving a high production speed of 3 meters per minute. Close cooperation with material partners Covestro, Huntsman, and Evonik makes processing highly reactive matrix materials possible.

Thermoplastic composite pultrusion expert—French CQFD has developed an in-situ pultrusion process, where fiber yarns or fabrics are pulled under external force, impregnated with caprolactam monomer and initiator, then formed and heated polymerized inside a shaping mold to produce the final product. The fiber volume fraction of products formed by this process can reach 70%, and the tensile modulus along the fiber direction can reach 60 GPa (reinforcing fibers are glass fibers), offering excellent specific strength and specific modulus. This process is applied in the FRTP crash beam jointly developed by CQFD, PEO, and Hyundai Motor, where the main body is formed using the in-situ pultrusion process with continuous glass fiber reinforced PA6 (commercial name C-SHOCK®), followed by overmolding to introduce mounting points for the crash beam. The entire solution reduces weight by 43% (3.7 kg) compared to metal beam solutions. With the potential cost reduction of carbon fiber in the coming years, this breakthrough concept will help the automotive industry achieve weight reduction goals to meet energy-saving targets (Figure 6).

◆ Molding

Molding involves cutting and stacking thermoplastic prepregs, placing them into a mold for heating, and once the temperature reaches the forming temperature, applying pressure with a press to cure and obtain plates, sheets, or other simple-shaped products. This method typically completes the forming cycle within tens of seconds to a few minutes, with low energy consumption and production costs, and high productivity. It is currently the most common forming method in FRTP processing, mainly used to produce car doors, dashboards, front-end frames, interior panels, etc.

For some complex features, mounting positions, and reinforcements, molding alone is difficult to achieve, so molding combined with injection molding processes have appeared on the market, such as ENGEL's Organomelt process, KraussMaffei's FiberForm process, and Bore's OIHM process.

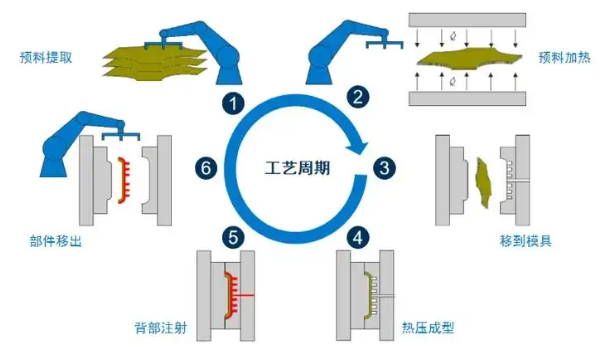

KraussMaffei first introduced the FiberForm process at the 2018 NPE exhibition in the United States. It is a perfect combination of thermoforming technology and injection molding, achieving a high degree of functional integration. It can be applied to seat brackets and backs, dashboard supports, door modules, side impact protection devices, battery brackets, and other components. The process consists of six steps (Figure 7): first extracting sheet prepregs, heating them in an oven, then moving to the mold for closing and hot pressing forming. On this basis, back injection molding is performed, and finally the mold is opened to remove the part. This process not only allows the combination of lightweight materials and designs to improve composite strength but also facilitates automation, enabling efficient production in compact spaces. The FiberForm technology reduces material usage while significantly lowering carbon emissions during material production, supporting the achievement of "dual carbon" sustainable development goals.

◆ Resin Transfer Molding (RTM)

The Resin Transfer Molding (RTM) process involves placing and clamping the reinforcement preform and inserts inside a mold, then injecting resin at a certain temperature and pressure through designated injection ports, followed by curing and demolding to obtain the product. This method requires relatively low equipment and mold costs, low investment, and low production costs. It can produce large products that other pressure forming methods cannot manufacture, suitable for products weighing 15 to 25 kg. It is a rapidly developing advanced composite forming process suitable for multi-variety, medium batch, and high-quality production, mainly used for automotive body panels, bumpers, gearbox housings, small truck cargo boxes, etc.

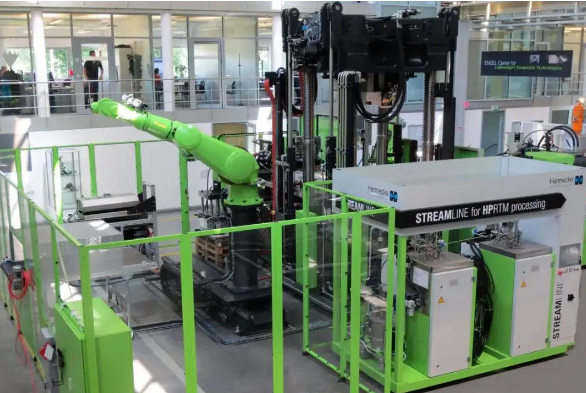

For efficient production of large, sturdy lightweight structural parts, ENGEL's HP-RTM high-pressure resin transfer molding technology is used, where dry fiber semi-finished products are impregnated with injected resin and then cured under heating conditions. This can produce flat automotive parts with better formability and high quality, such as high-quality and sturdy roof systems and body parts (Figure 8).

Market Status and Prospects

Although FRTP is regarded by many as the next material technology breakthrough, its application remains limited over the years, and its penetration in the domestic market has not met expectations. The reasons may be found in technology, performance, and cost aspects.

Firstly, compared with thermoset composites, FRTP often has higher initial costs, higher processing temperatures, and usually higher tooling and mold costs. Traditional part manufacturers may be unfamiliar with modern FRTP processing technologies, amplifying perceived limitations and considering FRTP inferior to thermoset composites. The advantages and utilization value of FRTP have not been fully recognized and developed, directly affecting normal market demand growth and hindering further development and application of FRTP from the supply and demand source. Secondly, FRTP manufacturing technology requirements are high, limiting some companies with insufficient technical level and production capacity from entering. Furthermore, raw material costs are high; high-end thermoplastic resin prices are tens of times that of ordinary thermoset epoxy resins. Coupled with high manufacturing technology requirements, these factors make FRTP, especially composites using high-end thermoplastic resins like PEEK and PI as matrices, prohibitively expensive, suppressing downstream application demand. Finally, China still lacks key technologies and equipment related to material preparation and structural forming.

Nevertheless, once technology quality meets requirements, prices and costs fall within market-acceptable ranges, and scientific research achievements are well transformed into productivity, with the rapid development of industries such as aerospace manufacturing, automotive, electronics and electrical, wind energy, high-end medical equipment, and intelligent machinery, China's FRTP industry will usher in a new development stage, gaining more market opportunities and share space in the coming years. The prospects remain promising.

Disclaimer For the sole purpose of exchanging and sharing composite material expertise and market information, not for any commercial purposes. If there are copyright issues or content disputes, please contact us immediately. We will handle them promptly.

Related News