Several impregnation methods for continuous fiber-reinforced thermoplastic composites

Release time:

2025-04-03

The impregnation methods for continuous fiber reinforced thermoplastic composites mainly include solution impregnation, melt impregnation, powder impregnation, slurry resin deposition, commingling, film stacking, and reactive impregnation.

The impregnation methods for continuous fiber-reinforced thermoplastic composites mainly include solution impregnation, melt impregnation, powder impregnation, slurry resin deposition, commingling, film lamination, and reactive impregnation.

01. Solution impregnation

Solution impregnation involves dissolving the resin in a suitable solvent to reduce its viscosity to a certain level. Then, the process used for impregnating thermosetting resins is used to wet the fibers. Finally, the solvent is removed by heating.

Advantages of solution impregnation: Overcomes the drawback of high melt viscosity of thermoplastic resins, enabling good fiber impregnation; simple preparation process and equipment.

Disadvantages of solution impregnation: The solvent must be completely removed, otherwise the solvent resistance of the product will decrease; physical delamination occurs during solvent removal, permeation along the resin-fiber interface, and solvent may accumulate in the pores and gaps on the fiber surface, resulting in poor resin-fiber interface and affected solvent resistance; solvent evaporation and recovery are expensive and pollute the environment.

Despite this, solution impregnation is still mostly used to prepare high-performance resin composites that are difficult to impregnate using other preparation techniques.

02. Melt impregnation

Melt impregnation is a preparation technique where thermoplastic resin is heated and melted to impregnate the fibers. This can be achieved in two ways: One is melt extrusion impregnation, which uses an extruder to feed the melt into a mold through which the fibers pass. The main factor affecting the melt extrusion impregnation process is the speed at which the melt polymer penetrates the fiber layer, which depends on the structure of the reinforcing material. Another is melt pultrusion impregnation, which uses a special pultrusion die. A bundle of uniformly dispersed, pre-stressed continuous fibers passes through a roller system where molten matrix resin flows between a series of rollers. Repeated alternating changes force impregnation of the fibers and melt, achieving the desired impregnation effect. However, this method can only be used to produce long fiber reinforced particles (typically 6-10mm in length) and not sheets.

In both methods, the pressure applied to the fibers is high, which can damage the fibers. The main advantage of melt impregnation is that it does not require any solvent.

03. Powder impregnation

In powder impregnation, resin fine powder is adsorbed onto the surface of the fiber filaments by electrostatic action in a fluidized bed. It is then heated to fuse the powder, and finally, the fibers are wetted during the molding process. Because impregnation is carried out in a dry state, the processing is not limited by the viscosity of the matrix, and polymers with relatively high molecular weight can be distributed into the fibers. The diameter of the polymer particles that can be adsorbed on the fibers is in the range of 5-25μm, and the resin powder diameter is preferably 5-10μm.

Advantages of powder impregnation: Less fiber damage, no polymer degradation; fast processing speed and low cost.

Disadvantages of powder impregnation: Wetting is only completed during molding, and powder is easily lost; the time, temperature, and pressure required for wetting depend on the size and distribution of the powder particles.

04. Slurry resin deposition

The process of slurry resin deposition is similar to that of papermaking. Glass fibers with a short cut length of 6-25mm, resin powder, and emulsifier are dispersed in water to form an aqueous suspension. A flocculant is then added to cause coagulation on the filter screen of a hydraulic molding machine, separating the coagulant from the water, hot-pressing the felt-like coagulant, and melting it into a sheet.

Advantages of slurry resin deposition: Good fiber dispersion, less breakage, less heat, high production efficiency; Disadvantages: High technical difficulty and high equipment cost.

05. Commingling

Commingling involves tightly combining thermoplastic resin spun into fibers or film strips with reinforcing fibers in a certain proportion to form a mixed yarn. Then, it passes through a high-temperature sealed impregnation zone to melt the resin fibers into a matrix. Ordinary weaving processes can easily make the mixed fibers into fabrics. The more uniform the mixing, the less pressure is required during curing. The ideal state of mixing is that each reinforcing fiber is adjacent to the matrix fiber, but because of the large difference in physical properties between the reinforcing fiber and the matrix fiber, this is difficult to achieve in practice. Commingling has good processability, easy control of resin content, sufficient fiber wetting, and the mixed yarn can be woven into various complex shapes, including three-dimensional structures, and can also be directly wound to produce composite materials with excellent properties.

However, this technique is not suitable for fiberglass composites and the molding of daily necessities or low-temperature thermoplastic engineering materials.

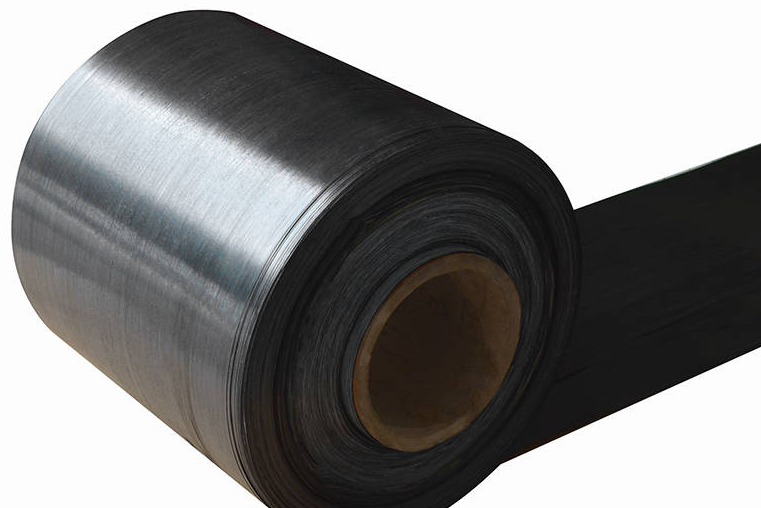

06. Film lamination

Film lamination involves stacking fiber-reinforced material layers and thermoplastic sheets, heating and pressing to allow the polymer melt to flow between the reinforcing materials, and then curing. The pressure applied in film lamination must be sufficient to allow the melt to enter between the fiber layers without causing flow between the reinforcing layers. Typical pressure values are less than 2.0 MPa. The composite after cooling should be free of voids, and vacuum-assisted pressing can ensure a void-free sheet. This method is widely used for molding sheets with complex surface shapes.

Advantages of film lamination: High-quality laminated products can be produced, but due to the high viscosity of the melt, higher pressure is required;

Disadvantages of film lamination: High resin content leads to high cost; the high viscosity matrix resin is difficult to infiltrate into the fibers.

07. Reaction impregnation method

The reaction impregnation method utilizes the characteristics of monomers or prepolymers with low initial molecular weight, low melt viscosity, and good fluidity, which can fully infiltrate the fibers. It prepares continuous fiber-reinforced thermoplastic resin matrix composites through in-situ polymerization. However, this process has harsh conditions and the reaction is difficult to control, and it has not yet been industrialized.

Disclaimer: This article is only for the exchange and sharing of composite material professional knowledge and market information, and is not for any commercial purpose. If you have any doubts about the copyright of the article or the accuracy of its content, please contact us immediately. We will deal with it in time.

Related News