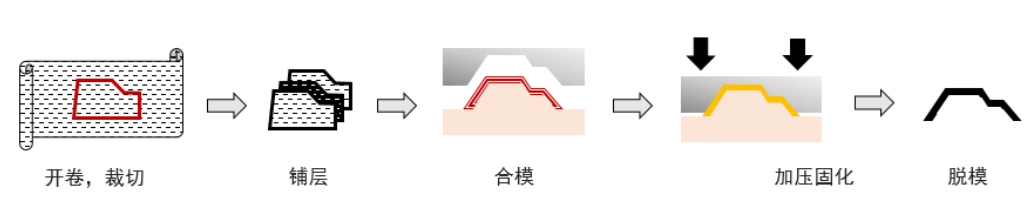

The whole process of carbon fiber SMC compression molding

Release time:

2025-04-03

SMC (abbreviation of Sheet Molding Compound, that is, sheet molding compound), carbon fiber SMC is a sheet molding compound formed by infiltrating short-cut carbon fiber, matrix resin, additives and other materials according to a certain ratio and using professional molding processing equipment according to a certain process.

1. Overview of carbon fiber SMC molding

1. Carbon fiber SMC

SMC (abbreviation of Sheet Molding Compound, that is, sheet molding compound), carbon fiber SMC is a sheet molding compound formed by infiltrating short-cut carbon fiber, matrix resin, additives and other materials according to a certain ratio and using professional molding processing equipment according to a certain process.

2. Carbon fiber SMC molding

It refers to the process of cutting and cutting the carbon fiber SMC sheet according to the requirements of product size, shape, thickness, weight, etc., and then stacking the cut material into the heated metal mold cavity, and curing and forming according to the pre-set process molding conditions;

There are many advantages of SMC molding process, such as it has simple operation, easy to achieve automation, short production cycle, smooth surface and complex structure of products, etc., can be embedded metal molding, low waste, etc., in addition to the application of carbon fiber SMC molding process to obtain products, its performance is also very good: excellent mechanical properties, thermal stability, chemical corrosion resistance, low shrinkage and low water absorption.

Second, carbon fiber SMC molding process

1. Material inspection

The quality of carbon fiber SMC sheet has a great impact on the molding process and product quality. Therefore, it is necessary to understand the quality of the material before pressing, such as resin type, fiber content, areal density and single weight, film peelability, and whether the material is expired, whether the fiber impregnation is good, whether there are impurities, whether the film is covered with damage, material hardness and quality uniformity, etc.

2. Material cutting

The material is thawed until there is no water mist on the surface of the PE bag and then cut, and the shape and size of the sheet are determined according to the structural shape of the product, the feeding position and the process. The size is mostly 70%-100% of the projection area on the surface of the product. In order to prevent contamination by external impurities, the upper and lower films are removed before loading, and the working area is kept clean to avoid foreign matter.

3. Adjust the parameters of the press

(1) It mainly includes pressure, temperature and molding time, which is determined according to product thickness, material requirements, mold conditions, etc.;

(2) The mold installation must be horizontal, and ensure that the installation position is in the center of the press table.

4. Clean the mold

(1) The mold should be thoroughly cleaned first, and the release agent should be applied, and the release agent should be wiped evenly with clean gauze before feeding, so as not to affect the appearance quality of the product. For new molds, it must be de-oiled before use;

(2) Clamping and heating mold.

5. Confirm the mold temperature

(1) Open the mold, use a contact thermometer to measure the temperature of the upper and lower mold of the cavity (note: before, after, left, middle and right, measure a few more points to ensure that the surface temperature of the mold reaches the pressing temperature required by the material, and the temperature of the mold core is about 5 degrees lower than the mold cavity);

(2) If the temperature is not reached, clamp the mold and wait for continued heating;

(3) If the temperature reaches the temperature, spray the release agent on the upper and lower molds again.

6. Confirm the amount and area of feeding

(1) Feeding amount: The feeding amount of each product can be calculated as follows when pressing for the first time: feeding amount = product volume * density 1.5g/c㎡;

(2) Feeding area: The size of the feeding area directly affects the density of the product, the flow distance of the material and the surface quality of the product, which is related to the flow and curing characteristics of SMC, the performance requirements of the product, the mold structure, etc. Generally, the feeding area is 70%-100%. Too small will cause fiber orientation due to too long process, reduce strength, increase waviness, and even fail to fill the cavity;

(3) Feeding position: The feeding position and method directly affect the appearance, strength and directionality of the product. Normally, the feeding position of the material should be in the middle of the mold cavity. For asymmetrical and complex products, the feeding position must ensure that the material flow reaches all ends of the mold forming cavity at the same time. 7. High temperature and high pressure molding

When the material block enters the mold cavity, the machine is started and the press goes down quickly. When the upper and lower molds are anastomosed, the required molding pressure is slowly applied, and after a period of heat preservation and pressure retention, the product molding is completed. In the molding process, the molding process parameters should be reasonably set according to the material characteristics and press conditions.

Molding temperature: The molding temperature depends on the curing system of the resin paste, the thickness of the product, the production efficiency and the complexity of the product structure. The molding temperature must ensure that the curing system initiates and crosslinks the reaction smoothly and achieves complete curing. Carbon fiber SMC molding temperature is generally between 130-140°C. In general, the molding temperature of thick-walled products should be lower than that of thin-walled products, which prevents excessive heat build-up in thick products at excessively high temperatures. The increase of molding temperature can shorten the corresponding curing time; Conversely, when the molding temperature decreases, the curing time needs to be extended accordingly. The molding temperature should be selected as a trade-off between high curing speed and optimal molding conditions.

Forming Pressure:The SMC molding pressure varies with the structure, shape, size and thickening of the SMC. Products with simple shapes need less pressure, and products with complex shapes need more pressure. The higher the degree of SMC thickening, the greater the molding pressure required, and the products with high requirements for appearance performance and smoothness require a higher molding pressure during molding. In conclusion, there are many factors that should be considered in determining the forming pressure. Generally speaking, the carbon fiber SMC molding pressure is between 10-25Mpa.

Molding time: The curing time (also called holding time) of carbon fiber SMC at the molding temperature is related to its properties and curing system, molding temperature, product thickness and color and other factors. Carbon fiber SMC molding time is usually between 10-15 minutes.

Since SMC is a fast curing system, fast closing of the press is important. If the press closes too slowly after feeding, it is easy to pre-cure patches on the surface of the product, or there is a shortage of material, or the size is too large. At the same time of rapid closing, the closing speed of the mold should be carefully adjusted at the end of the press stroke, and when the mold is closed at a certain distance, the closing speed should be slowed down to facilitate exhaust.

8. Demoulding and appearance inspection

(1) The upper mold is opened slowly, and after it rises to 10mm, confirm whether the product is stuck in the mold, and move the upper mold to the upper limit after confirming that the product is left in the lower mold. Open the top mold mechanism and slowly lift the product to take it out;

(2) Check the appearance of the product to see if there is a shortage of materials, dirt, pores, dry yarn, etc., such as the product without painting needs to repair the overflowing burr to complete the production of products.

Disclaimer: It is only used for the exchange and sharing of composites expertise and market information, and is not used for any commercial purposes. If you have any questions about the copyright of the article or the content, please contact us. We will deal with it in a timely manner.

Related News