Introduction of composite material PCM process

Release time:

2024-08-06

The PCM molding process is a process in which a semi-finished carbon fiber composite material that has been stamped is put into a mold and molded by a contour scanning spray curing process. This process first needs to design the cast, and through the three-dimensional computer processing to obtain the three-dimensional model of the cast, from its data conversion to obtain the layered pattern cross-sectional profile data, to generate control information. Then, the resin nozzle is controlled on the PCM rapid prototyping machine to evenly spread the resin on the surface of the core sand, and the curing of the model is preheated and accelerated after one layer is completed. The PCM molding process, also known as compression molding, is a molding method in which the stamped semi-finished carbon fiber composite material is pre-placed into a mold, and then heated and pressurized to form and solidify. Among them, the forming blank before hot pressing is the key to realize rapid manufacturing.

The PCM molding process is a process in which a semi-finished carbon fiber composite material that has been stamped is put into a mold and molded by a contour scanning spray curing process. This process first needs to design the cast, and through the three-dimensional computer processing to obtain the three-dimensional model of the cast, from its data conversion to obtain the layered pattern cross-sectional profile data, to generate control information. Then, the resin nozzle is controlled on the PCM rapid prototyping machine to evenly spread the resin on the surface of the core sand, and the curing of the model is preheated and accelerated after one layer is completed. The PCM molding process, also known as compression molding, is a molding method in which the stamped semi-finished carbon fiber composite material is pre-placed into a mold, and then heated and pressurized to form and solidify. Among them, the forming blank before hot pressing is the key to realize rapid manufacturing.

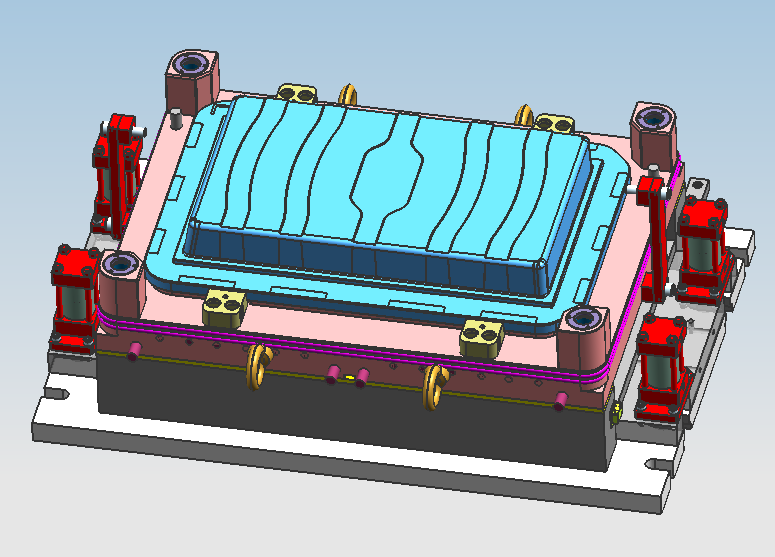

Figure -1 PCM Mould

Features of the PCM molding process include:

1, design flexibility: according to the design requirements of the rapid production of complex geometry and rich details of the components.

2, material adaptability: suitable for a variety of carbon fiber composite materials, including prepreg and non-prepreg form.

Efficient production: Compared with traditional manual or semi-automated manufacturing methods, PCM molding process can significantly improve production efficiency and product quality.

4. Cost-effectiveness: Although the initial investment may be high, in the long run, cost savings can be achieved by reducing material waste and improving production efficiency.

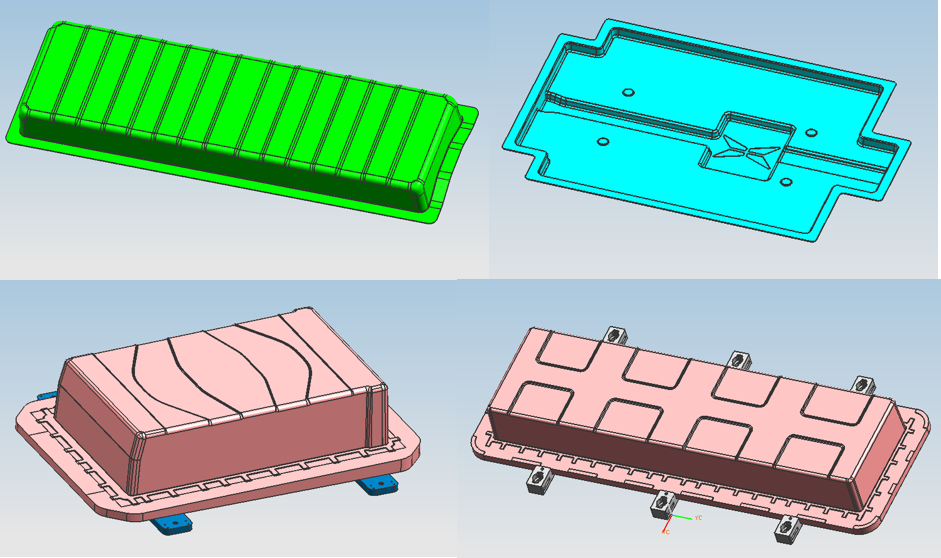

Figure -2 PCM moving mode

PCM molding process is widely used in many fields, including but not limited to aerospace, automobile manufacturing, sports equipment, etc., among which carbon fiber composite materials are favored because of their light weight, high strength and good corrosion resistance. This process is not only suitable for the production of large structural parts, but also for the manufacture of small complex parts, to meet the needs of different industries for high-performance, lightweight components.

Related News