Exploring the Development of Aircraft Composite Materials Through New Materials and Advanced Manufacturing Processes

Release time:

2025-09-02

The amount of advanced composite materials used is an important indicator for measuring the sophistication of large civilian passenger aircraft.

Exploring the Development of Aircraft Composite Materials Through New Materials and Advanced Manufacturing Processes

The amount of advanced composite materials used is a key indicator of the sophistication of large civilian passenger aircraft. In recent years, the use of composites in various aircraft models has steadily increased. For instance, the most advanced wide-body passenger jets from Boeing and Airbus—such as the B787 and A350—feature composite structures that now account for more than 50% of the aircraft's total structural weight. Similarly, China's domestically developed wide-body passenger aircraft will also achieve a comparable level of composite material usage in its airframe design. However, as traditional composites continue to dominate at such high proportions—covering components like fuselages and wings—the next critical challenge becomes clear: how to further advance aerospace composites to meet growing demands for higher performance, greater efficiency, lower costs, and sustainability. Fortunately, the emergence of numerous new materials and innovative manufacturing processes in recent years has been driving the development of advanced composites toward these very goals, paving the way for even broader and more sophisticated applications of composites in commercial aviation.

Authors: Yang Yang, Yuan Yuhui

Application of Aeronautical Composite Materials

Currently, the civilian airliner with the highest usage of composite materials is Airbus's A350 aircraft, where composites account for 53% of the structural weight. Following closely is Boeing's B787, with composites making up 50% of its structure. Structurally, key components such as the aircraft fuselage and wings are primarily manufactured using carbon fiber composites. Many secondary load-bearing parts—like rudders, elevators, flaps, and ailerons—are also constructed from composite materials. Large primary load-bearing components entirely rely on high-performance epoxy-based carbon fiber composites, while some secondary load-bearing parts utilize advanced non-autoclave manufacturing techniques, such as liquid molding and compression molding (e.g., spoilers and window frames). Overall, the proportion of composite materials in these aircraft exceeds 50%, with more than 90% produced via autoclave processes. The primary material selection focuses on high-performance epoxy-carbon fiber composites, with a smaller portion reinforced by glass fibers. In terms of production capacity, Airbus plans to increase A350 output to 12 aircraft per month by 2028, while Boeing’s B787 has historically achieved a peak production rate of approximately 13 aircraft per month.

The implementation of the aforementioned aircraft models has taken the application of advanced composite materials in civil aviation to new heights. Technologies related to the design, manufacturing, and verification of composite components continue to advance steadily, pushing the boundaries of their current configurations closer to their operational limits. Looking ahead, the use of composites will shift from quantitative expansion to qualitative transformation, as many new materials and innovative processes rapidly mature—and these breakthroughs will propel civil aircraft composites toward even greater levels of sophistication. This trend will become especially pronounced in next-generation aircraft models.

Composite Material Liquid Molding Technology

As the use of composite materials in commercial aircraft continues to rise, issues such as the complexity of prepreg manufacturing processes, the high costs associated with autoclave curing of composites, and the expense of assembly procedures have become increasingly pronounced. To address these challenges and eventually replace autoclave technology, Europe, North America, and Russia have progressively developed a series of research and development programs focused on low-cost composite manufacturing techniques since the 1990s through to 2030. These initiatives include the Composite Aeronautics for Affordable Innovation (CAI) program, the Advanced Composites Technology Initiative (ACT), the Aircraft Efficiency and Cost-Effective Engineering (ACEE) program, the Advanced Subsonic Technology (AST) project, the Advanced Low-Cost Airframe Structures (ALCAS) initiative, and the recent Technology Application for Near-Term Commercial Goals and Objectives (TANGO) program. During this period, various liquid molding technologies have emerged, giving rise to modern processes such as Resin Transfer Molding (RTM), Vacuum-Assisted Resin Infusion (VARI), and Resin Film Infusion (RFI). Today, liquid molding techniques for composites have become the primary non-autoclave methods for manufacturing resin-based composite materials, gradually gaining traction in both domestic and international aerospace industries. In recent years, thanks to advancements in process automation and improvements in key raw materials—such as higher-performance carbon fibers and more durable epoxy resins—this technology is rapidly expanding into applications involving critical load-bearing structures, including components like the wings of the A220 and MC-21 aircraft.

Traditional low-cost liquid molding techniques primarily rely on manual fabric placement combined with resin infusion methods to produce parts. This process has been successfully applied in the manufacturing of components such as the flaps and moving panels for the B787, keel beam corner pieces for the A350 and A380, as well as leading-edge slats, beams, window frames, and cabin doors for a certain domestic aircraft model. The widespread adoption of liquid molding technology has significantly reduced both the manufacturing costs and assembly requirements for these complex structural parts.

With the advancement of materials technology and manufacturing processes, liquid molding-produced composite materials are rapidly expanding their applications—from small-scale secondary load-bearing structures to large-scale primary load-bearing ones.

With the advancement of equipment and automation technologies—such as large-scale, heatable molds and automated dry-fiber placement systems—liquid-molding composite structures have continuously pushed size boundaries. From early applications of RTM processes to produce small components, the technology has evolved toward manufacturing larger-scale structures. For instance, by leveraging automated equipment and complementary VARI molding techniques, Bombardier’s C Series aircraft and Russia’s MC-21 jet have successfully produced liquid-molded wing parts measuring over 16 meters in length.

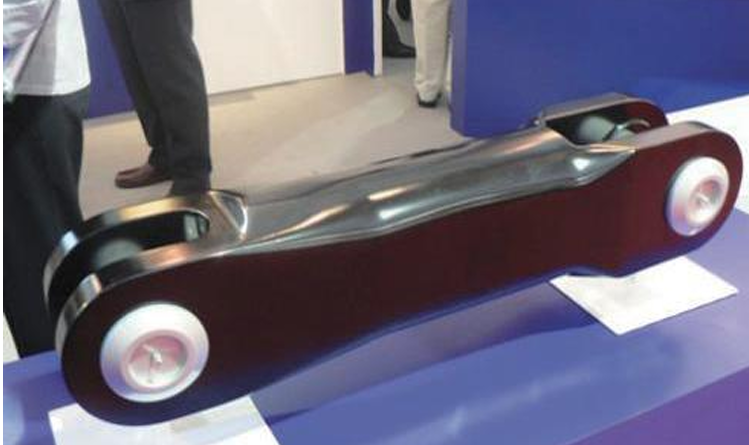

Meanwhile, this process has also been steadily expanding—from secondary load-bearing structures to primary load-bearing ones. Initially, liquid-molded composite materials were primarily used in non-load-bearing or secondary-load-bearing components such as cabin doors, control surfaces, and fairings. Today, however, they are gradually making their way into critical primary load-bearing structures like landing gear, wings, wing spars, and the fuselage itself—examples include the B787 landing gear struts and the MC-21’s wings and wing spars. Even Spain’s MTorres company has taken innovation a step further by experimenting with the VARI dry-fiber placement process to produce an all-in-one composite fuselage for general-purpose aircraft.

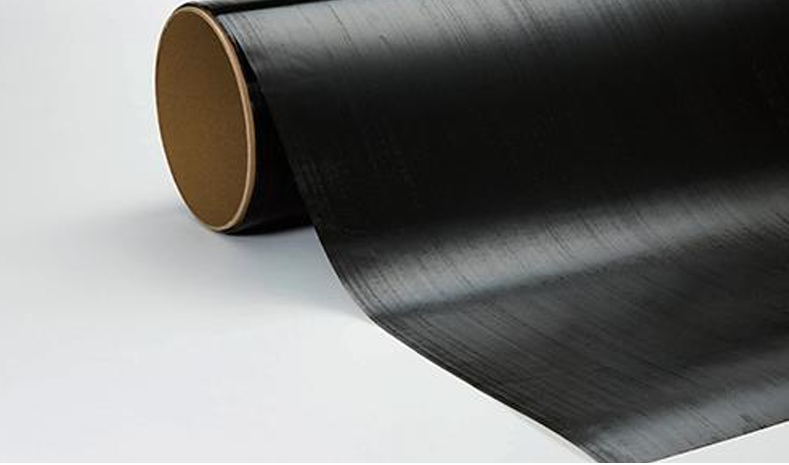

The realization of the aforementioned primary load-bearing structure has also been made possible by the continuously improving overall performance of liquid-molding composite materials, which are gradually approaching the performance levels of prepreg autoclave-cured composites. Thanks to ongoing advancements in both fiber materials and epoxy resin properties, the impact-after-compression (CAI) strength—once considered a key performance limitation of liquid-molded composites—has now reached the standards set by next-generation prepreg autoclave-cured composites. For instance, liquid-molded composites fabricated using Hexcel’s HiTape® or Cytec’s DryTape® dry fibers have even achieved CAI values exceeding 300 MPa.

Due to its advantages—such as eliminating the need for prepreg materials, enabling full-scale molding, and removing the requirement for autoclave curing—the liquid molding process offers significant cost benefits in manufacturing. As automation levels increase and process simulation technologies advance, the consistency and reliability of its products will continue to improve. Looking ahead, it holds great promise for large-scale applications and mass production of high-strength, load-bearing structural components.

Thermoplastic Composite Materials Technology

Aerospace thermoplastic composites and their application technologies have seen rapid development in recent years. Compared to thermoset composites such as those based on epoxy resins, thermoplastic composites boast outstanding advantages, including high toughness, excellent flame retardancy, superior resistance to moisture and heat, and ease of recycling. In terms of manufacturing processes, thermoplastic composites can be produced using a variety of non-autoclave techniques, such as compression molding, pultrusion, and in-situ consolidation. Additionally, their short molding cycles—since there’s no chemical curing process involved—eliminate the need for costly low-temperature transportation and storage of raw materials. As a result, thermoplastic composites not only help reduce costs but also maintain high production efficiency.

In the European Union's "Clean Sky" initiative, researchers are experimenting with thermoplastic composites to build the airframe structures of next-generation narrow-body passenger aircraft. The goal is to reduce weight by more than 20% compared to current aluminum alloy structures, while also aiming for a monthly production capacity of 100 aircraft—all without compromising manufacturing efficiency—in order to enhance the advanced capabilities of narrow-body jets.

Currently, the project has completed the manufacturing and assembly of the integral cylindrical section made from thermoplastic composite materials. During the manufacturing process, several advanced technologies were validated, including the in-situ consolidation of thermoplastic prepreg for the fuselage skin and its subsequent autoclave molding. Additionally, stringers, frames, and corner pieces were produced using compression and stamping techniques, while the floor beams were fabricated using an automated prepreg layup combined with autoclave molding.

Meanwhile, the use of thermoplastic composites has made welding between components possible. This reduces the need for drilling holes in composite materials and eliminates the extensive use of fasteners. As a result, weight is reduced while simultaneously enhancing assembly and connection efficiency. In particular, thermoplastic composite welding technology is widely employed in the manufacturing of fuselage skin panels. Specifically, ultrasonic welding is used to join stringers with skins, resistance welding is applied for attaching frames to the fuselage, and innovative laser welding technology has been adopted in the assembly of upper and lower fuselage skin panels. These advanced welding techniques provide new options for connecting and assembling composite parts.

In the TheHi-Rate Composite Aircraft Manufacturing (HiCAM) research program, led by NASA's Langley Research Center in the United States, aerospace thermoplastic composite manufacturing technology is also designated as a key research project. The program primarily focuses on three areas: thermoplastic composite molding techniques, assembly technologies, and automated fiber placement methods. The overall goal of the HiCAM project is to achieve an efficient production rate of 60 to 80 aircraft-equivalent units per month for all-composite aircraft components—through the development of multiple high-efficiency manufacturing technologies, including those for thermoplastic composites—while simultaneously reducing manufacturing costs by 30% to 50%.

Driven by the aerospace industry's growing demand for manufacturing efficiency, thermoplastic prepregs and related technologies continue to advance. With their advantages of repeatable processing and flexible manufacturing methods, these materials are paving the way for low-cost, high-efficiency production and sustainable development in aerospace composites. Today, thermoplastic composites and their associated technologies have emerged as one of the fastest-growing areas, with research and applications steadily gaining momentum, yielding a steady stream of innovative breakthroughs. Meanwhile, large-scale adoption in next-generation aircraft models is already on the horizon, poised to become a key driver of future growth in advanced composite material applications within the aviation sector.

Green Composite Materials Technology

Greening composite materials and their products is a crucial approach to driving the sustainable development of composites. Specifically, this involves developing composites made from recyclable, natural raw materials and applying them to the structural manufacturing of civil aircraft—particularly in interior components. As the proportion of composite materials used in civil aircraft continues to rise, their widespread adoption has given rise to new challenges, such as resource recycling and environmental impact. In 2013, the European Union government launched its largest-ever research and innovation framework program, "Horizon 2020," where "Sustainable Development and Natural Resources" ranked second among the five key funding areas—this category explicitly includes green aviation composites. Similarly, China’s 13th Five-Year Plan and the "Made in China 2025" initiative have repeatedly emphasized the concept and targets of "green manufacturing." As a result, the development of "green aviation composites" has become a global focus and area of intense research and attention across countries today.

Currently, green composite materials are mostly in the research and validation stage. They primarily utilize biodegradable polymer materials, biomass resins derived from plant resources, plant-based fiber materials, and eco-friendly paper honeycomb structures to develop composites that deliver comparable performance but are far more environmentally friendly. At the same time, researchers are actively exploring ways to enhance the materials' processability, flame retardancy, and mechanical properties. The development and application of green composites play an indispensable role in expanding the use of interior structural composites and driving the sustainable growth of aerospace composite materials.

New Prepreg Product

With advancements in materials technology, stronger fiber materials and high-performance polymer resins have continuously enhanced the properties of composite materials. Hexion Inc. of the United States was the first to introduce IM10 carbon fiber, which boasts a tensile strength approaching 7,000 MPa and a modulus exceeding 300 GPa. Later, Toray Industries launched its T1100/3960 prepreg system in 2021, featuring T1100 carbon fibers with a tensile strength of up to 7,000 MPa and a modulus of 324 GPa. The 3960 resin is a high-toughness epoxy designed for high-temperature curing, and this prepreg can be processed using non-autoclave curing methods. This innovation translates into lower manufacturing costs and lighter overall composite structures.

Toray Advanced Composites recently launched TC1130, a polyethersulfone-based carbon fiber prepreg designed for sandwich structures. Featuring excellent adhesion to honeycomb cores, this material effectively addresses the issue of low bonding strength typically associated with thermoplastic composites, making it ideal for a wide range of aerospace interior applications. As a result, manufacturing honeycomb sandwich structures has become more convenient, while also enhancing the durability of the final products.

The new materials, boasting superior performance and richer functionality, not only expand the application scope of aerospace composites but also continuously enhance the performance of existing components. As a result, the utilization of composite material structures will yield even greater benefits!

Conclusion

Looking back at the history of commercial aircraft development, the application technologies and capabilities of composite materials have continuously advanced, while innovative developments in this field are evolving at an astonishing pace! The next generation of aircraft is sure to elevate composite material technology to entirely new heights. The ongoing maturation and widespread adoption of new materials and cutting-edge manufacturing processes have powerfully propelled the high-level advancement of composites in commercial aviation. Among these, liquid molding technology, thermoplastic composites, eco-friendly green composites, and next-generation prepreg products with superior performance stand out as key areas for technological innovation—each holding significant industrial value. Domestically, there is a pressing need to increase investment and strategic planning in these critical areas, ensuring both technical and policy support for the advanced application and sustained growth of composite materials in commercial aircraft, thereby better equipping ourselves to meet future challenges and seize emerging opportunities!

Statement: This article is intended solely for the exchange and sharing of expertise in composite materials and market insights, and is not meant for any commercial purposes. If individuals or organizations have any doubts regarding the copyright of the article or the authenticity and accuracy of its content, please contact us immediately. We will address your concerns promptly.

Related News