Mold management need to pay attention to what issues

Release time:

2024-08-02

Mold management can be divided into three different parts, namely mold development, mold use and mold maintenance, therefore, the effective management of the mold, we can start from the process, improve the management of each part.

Mold management can be divided into three different parts, namely mold development, mold use and mold maintenance, therefore, the effective management of the mold, we can start from the process, improve the management of each part.

First of all, in the mold development, the need to set up a mold development team, appointed project manager, project designer, contact person to monitor the development process.

Hold a mold development meeting to discuss product characteristics, steel types, mold life, precision requirements, mechanical specifications, the impact of finished product shape on the mold, and evaluate the development time first. Through the above management methods, enterprises can not only obtain more accurate evaluation, but also train new employees in mutual communication;

At the same time, enterprises should monitor the actual progress of the project. If you use project monitoring tools, predict and calculate the actual progress schedule, compare the actual progress of the project with the planned progress, correct any errors that deviate from the plan, and make appropriate responses in a timely manner. For example, use different masters to be responsible for wire cutting, processing, polishing, heat treatment, etc;

This is not only easier to train technical staff, but also do not have to rely on one or two technical talents, so that the loss of brain drain to reduce. However, in this process, the instructions of the process should be standard and clear. In addition, in the face of short lead times, some tasks can be outsourced so that the company can concentrate resources on its core work.

Secondly, in the use of molds, attention should be paid to the difficulties often encountered in extraction, mold assembly and mold test, manufacturing and recycling, such as the mold cannot be found or the mold is damaged and cannot be used. After mold installation and mold test, it was found that the mold needed maintenance. During manufacturing, we did not pay attention to the expiration of the mold life, thus affecting the product quality. The used mold did not record its state, resulting in delayed production deadline when it was reused in future.

For these problems, it is necessary to record the use of the mold each time and information, because recording the number of stamping molds is of great help to evaluate the life of the mold. At the same time, the practice of regular or fixed maintenance treatment, depending on the situation to determine whether the need for maintenance, provide mold has been used data, let customers assess the impact of mold on product quality, decide whether to build a new mold.

In addition, to unify the management of mold entering and leaving the warehouse, special personnel are required to be responsible for the borrowing and return of molds, and all entering and leaving shall be recorded and signed.

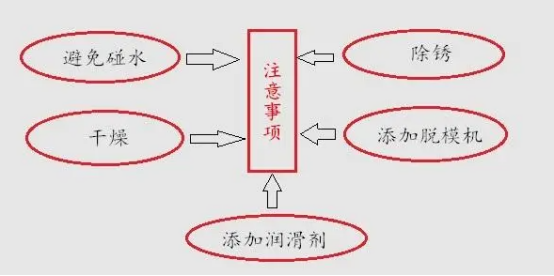

In terms of mold maintenance, each mold is recorded independently, and the mold also has an independent folder to record all changes and states that have been made, such as the life of the mold, the state of the mold, including abnormal loss; The mold should also be clearly classified, such as hardware, die casting, plastic, etc. In addition, it is necessary to develop a maintenance plan to carry out regular maintenance and management of the mold, thereby reducing the risk of damage and reducing maintenance costs.

Related News