Qualified Designer

Release time:

2024-08-02

Mold as the "mother of industry" plays an important role in the development of the national economy, our daily life of all kinds of daily necessities are inseparable from the mass production of mold. In the fields of electronics, automobiles, home appliances and communications, 60%-80% of parts rely on mold forming. The parts produced by the mold have high precision, high complexity, high consistency, high productivity and low consumption, which are unmatched by other processing technologies. The mold is also a "benefit amplifier", and the value of the final product produced by the mold is often dozens of times or hundreds of times the value of the mold itself. At present, the annual output value of molds in the world is about 60 billion US dollars, and the level of mold production technology has become an important symbol to measure the level of a country's product manufacturing.

What capabilities should a qualified mold design engineer have?

Foreword

Mold as the "mother of industry" plays an important role in the development of the national economy, our daily life of all kinds of daily necessities are inseparable from the mass production of mold. In the fields of electronics, automobiles, home appliances and communications, 60%-80% of parts rely on mold forming. The parts produced by the mold have high precision, high complexity, high consistency, high productivity and low consumption, which are unmatched by other processing technologies. The mold is also a "benefit amplifier", and the value of the final product produced by the mold is often dozens of times or hundreds of times the value of the mold itself. At present, the annual output value of molds in the world is about 60 billion US dollars, and the level of mold production technology has become an important symbol to measure the level of a country's product manufacturing.

With the development of society, people have higher requirements for the appearance of products, more diverse functions, and the corresponding requirements for molds are getting higher and higher. In order to derive a lot of new mold types and technologies, mold structure is becoming more complex, mold precision is more sophisticated, for the mold practitioners of the skill requirements are also getting higher and higher, the level of mold design also directly affects the quality of the mold.

For many mold friends engaged in mold design in the end should master what things? A qualified mold design engineer in the end should have what ability? These concepts are vague. Now make a unified summary for your reference.

What capabilities should a qualified mold design engineer have?

1. mechanical design

Mold is a mechanical product, need to master the knowledge and skills of mechanical design, can design a reasonable structure, reliable function of the mold.

2. Materials Science

The material selection of the mold has an important impact on the service life, production efficiency and product quality of the mold. It is necessary to understand the performance and scope of various materials and choose the most suitable material.

3. die steel/heat treatment

4. plastic raw materials/molding process

五、软件UG、CAD、MOLDFLOW、CATIA、Solidworks等

Most of the modern mold using numerical control processing technology, need to master the numerical control programming skills, but also need to use CAD/UG and other technologies, to skilled use of CAD/UG and other software, mold design and write efficient, accurate processing procedures.

6. mold processing technology

Need to master a variety of mold processing technology, such as milling, turning, EDM, wire cutting, etc., to be able to carry out mold processing and repair.

7. mold debugging and maintenance

It is necessary to debug and maintain the mold to ensure the stability and accuracy of the mold during use.

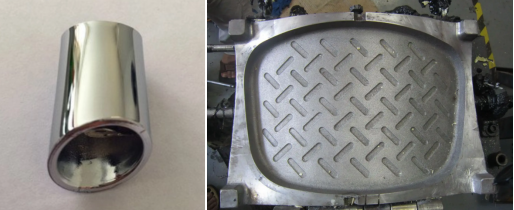

8. Surface Treatment Etching/Electroplating/Silk Screen/Painting

9. good communication skills

Mold engineers need to communicate with leaders, production departments, quality inspection departments, suppliers, users and other aspects, need to have strong communication skills, can accurately understand the needs and cooperate with others to complete the work.

Related News