Thermoplastic composite molding technology and applications

Release time:

2025-05-15

Thermoplastic composite molding is an advanced manufacturing technology that combines the advantages of thermoplastic materials and composite materials to achieve high-performance, high-precision, and efficient product manufacturing through molding processes.

Thermoplastic Composite Molding Technology and Applications

Thermoplastic composite molding technology is an advanced manufacturing technology that combines the advantages of thermoplastic materials and composite materials to achieve high-performance, high-precision, and efficient product manufacturing through molding processes. This article introduces thermoplastic composites, molding technology principles, application fields, advantages, and future development trends.

I. Introduction to Thermoplastic Composites

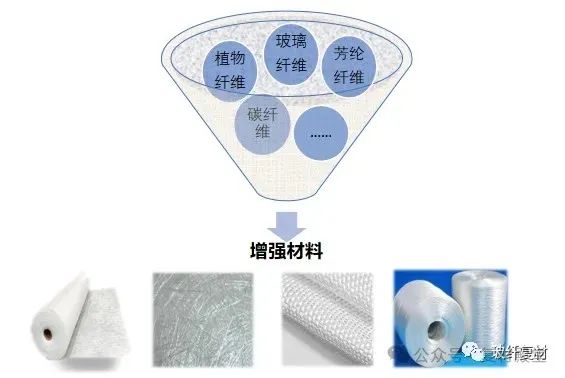

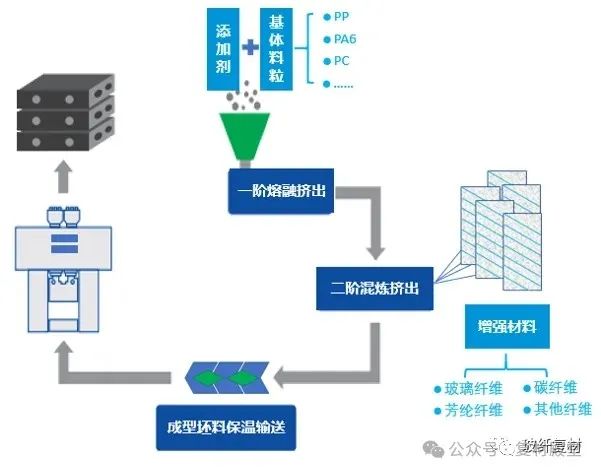

Thermoplastic composites are materials formed by using fibers (glass fiber, carbon fiber, aramid fiber, plant fiber, etc.) as reinforcing materials and thermoplastic resins (PP, PC, PA6, etc.) as the matrix. The thermoplastic resin is melted by heating and then impregnated into the fibers. Depending on the product performance and use, the reinforcing material can be in different forms such as continuous fiber felt, chopped fiber felt, fabric, and un-twisted roving.

II. Introduction to Thermoplastic Composite Molding Technology

Thermoplastic composite molding technology is an advanced production process mainly used in the processing of thermoplastic composites. This technology uses high temperature and high pressure to press thermoplastic composites into products with the required shape and performance. During the molding process, the material is heated and pressed, and the required shape and performance are obtained after cooling. This process has the characteristics of high molding temperature, high molding pressure, and short molding time, and can achieve the manufacturing of complex structures and high-performance products.

Advantages of Thermoplastic Composite Molding Technology

1. High Performance: Thermoplastic composite molding technology can produce high-performance products with excellent mechanical, thermal, and chemical properties.

2. High Precision: This process can achieve high-precision and high-complexity product manufacturing, meeting the application scenarios of various high-precision requirements.

3. High Efficiency: Thermoplastic composite molding technology has a short molding cycle and high production efficiency, suitable for mass production.

4. Energy Saving: Thermoplastic composite molding technology uses high-temperature and high-pressure processing methods, has high production efficiency, and can significantly reduce energy consumption.

5. Low Cost: Thermoplastic composites are widely available and inexpensive, significantly reducing production costs. In addition, thermoplastic composite molding technology can achieve mass production, further improving cost-effectiveness.

6. Excellent Product Performance: Thermoplastic composite molding technology can produce products with excellent properties, such as high strength, corrosion resistance, and high temperature resistance. These products not only have a longer service life but also improve safety, comfort, and environmental protection performance.

7. Environmental Protection: Thermoplastic composites can be recycled and reused, meeting the requirements of sustainable development and having good environmental protection properties.

8. Wide Range of Applications: Thermoplastic composite molding technology is applicable to the production of different fields and products, such as automobiles, aerospace, electronics, and building materials. The application of this technology can bring many benefits and improvements to various fields.

9......

IV. Introduction to Molding

Molding involves cutting and stacking thermoplastic prepreg, placing it in a mold, heating it to the molding temperature, and then pressing the prepreg layers with a press to solidify it into plates, sheets, or other simple shapes. The molding cycle of this method is generally completed within tens of seconds to minutes, with low energy consumption and production costs, high productivity. It is a common molding method in FRTP molding and is mainly used to produce car doors, instrument panels, front frames, and interior panels.

For some complex features, installation positions, and reinforcements, it is difficult to achieve using molding. Therefore, molding combined with injection molding has emerged in the market, such as Organomelt technology, FiberForm technology, and OIHM technology.

1. GMT Molding Technology

Glass fiber mat-reinforced thermoplastic composite (GMT) is a novel, lightweight composite material using thermoplastic resin as the matrix and glass fiber mat as the reinforcing material.

2. LWRT Hot Pressing Technology and Applications

LWRT Introduction Lightweight glass fiber reinforced thermoplastic composite (LWRT) consists of a thermoplastic resin matrix (usually PP) and chopped long glass fiber reinforcing material. It is made through chopping, loosening/mixing, needle-punched weaving, and hot-pressing composite.

3. LFT-D Molding Technology and Applications

LFT-D, in-line long fiber reinforced thermoplastic material, is short for Long Fiber reinforced Thermoplastics-Direct.

4. CFRTP Hot Pressing Technology and Applications

CFRTP Introduction Continuous fiber reinforced thermoplastic prepreg (CFRTP) is a lightweight and high-strength composite material using thermoplastic resin as the matrix and continuous fiber as the reinforcing material. The main molding forms of CFRTP include unidirectional prepreg (UD), fabric prepreg (Fabric), and other methods. Among them, unidirectional prepreg (UD) related products are currently one of the mainstream technologies.

5. Composite Molding Technology, Fiber-Form Molding Technology, etc.

V. Application Fields of Thermoplastic Composite Molding Technology

Thermoplastic composite molding technology is widely used in various fields, mainly in the automotive industry, aerospace, electronics, and building materials.

1. Automotive Industry: Thermoplastic composite molding technology can be used to produce automotive bodies and chassis components. Due to the advantages of lightweight, high strength, and corrosion resistance of thermoplastic composites, it can significantly reduce the weight of automobiles, improve fuel efficiency, and reduce environmental pollution.

2. Aerospace: Thermoplastic composite molding technology can be used to produce aerospace vehicle shells and seats. Due to the advantages of high strength, high temperature resistance, and corrosion resistance of thermoplastic composites, it can significantly improve the performance and safety of aerospace vehicles.

3. Electronics and Electrical Engineering: Thermoplastic composite molding technology can be used to produce housings and internal structural components for electronic and electrical products. Due to the advantages of thermoplastic composites such as environmental protection, fire resistance, and corrosion resistance, the safety and service life of electronic and electrical products can be improved.

4. Construction Materials: Thermoplastic composite molding technology can be used to produce construction materials such as building formwork and insulation materials. Due to the advantages of thermoplastic composites such as light weight, high strength, and corrosion resistance, the performance and service life of construction materials can be improved.

VI. Future Development Trends

With the continuous advancement and innovation of science and technology, thermoplastic composite molding technology will usher in more development opportunities and challenges. In the future, this technology will develop in the following aspects:

1. Material Innovation: Research and development of new thermoplastic resins and reinforcing materials to improve the comprehensive performance of composite materials and meet higher and more demanding application requirements. At the same time, strengthen basic research and improve the stability and reliability of materials.

2. Process Optimization: Further improve and optimize the thermoplastic composite molding process to improve production efficiency, reduce energy consumption, reduce waste generation, and achieve green manufacturing. Combine advanced manufacturing technologies and automated equipment to achieve intelligent and flexible production processes.

3. Intelligent Development: Introduce intelligent technology into the thermoplastic composite molding process to achieve automated, digital, and intelligent production processes, improving production efficiency and product quality.

4. Expanding Application Fields: Continuously expand the application fields of thermoplastic composite molding technology, especially in emerging industries such as new energy, environmental protection, and biomedicine, to promote industrial upgrading and development.

In summary, Thermoplastic composite molding technology, as an advanced manufacturing technology, has broad application prospects and huge development potential. In the future, with continuous technological innovation and the expansion of application fields, this technology will play an important role in more fields and make greater contributions to the development of human society.

Disclaimer : For the exchange and sharing of composite materials professional knowledge and market information only, not for any commercial purposes. If there are any copyright issues or questions about the content, please contact us immediately. We will deal with it promptly.

Related News