How is mirror electro-discharge machining performed on precision molds?

Release time:

2025-05-27

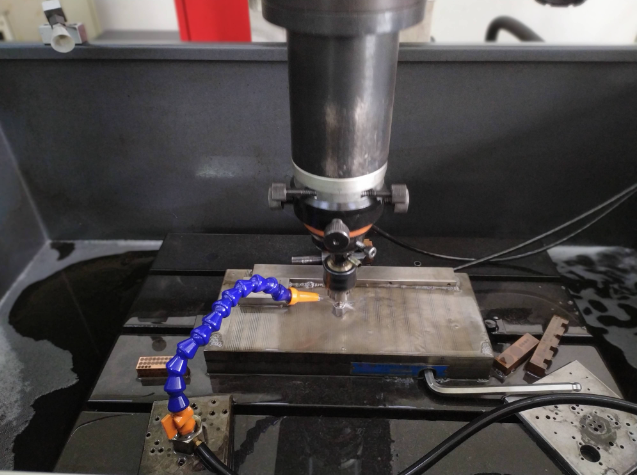

Electrical discharge machining (EDM) is widely used in the manufacturing of fine cavity molds. So-called "mirror EDM" generally refers to EDM with a surface roughness value of Ra < 0.2 um, resulting in a mirror-like reflective surface.

How to perform mirror-like EDM on delicate molds?

EDM is widely used in the manufacturing of delicate cavity molds. The so-called "mirror-like EDM" generally refers to EDM with a surface roughness value of Ra < 0.2 μm and a mirror-like reflective effect on the processed surface. Mirror-like EDM can replace manual polishing for some delicate processing, improving part quality and having practical significance.

EDM requires three conditions

1. Use a pulse power supply

2. Use an automatic feed adjustment device to maintain a small discharge gap between the tool electrode and the workpiece electrode.

3. The spark discharge must be carried out in a liquid medium with a certain insulation strength (10~107 Ω·m).

II. EDM has the following characteristics

It can process any high-strength, high-hardness, high-toughness, high-brittleness, and high-purity conductive materials; there is no significant mechanical force during processing, suitable for low-rigidity workpieces and micro-fine structure processing: pulse parameters can be adjusted as needed, and rough machining, semi-finishing, and finishing can be performed on the same machine tool; the surface of EDM presents pits, which is conducive to oil storage and noise reduction; production efficiency is lower than cutting; part of the energy is consumed on the tool electrode during the discharge process, resulting in electrode wear and affecting the forming accuracy.

III. Not all processing types can be performed with mirror-like EDM

The reason why EDM can achieve a mirror-like effect is directly related to the carbon black layer generated during EDM. If a uniform carbon black layer can be easily formed in the processing area, it means that a mirror-like effect is easy to obtain.

1. Simple shapes are easier to obtain a mirror-like finish than complex shapes. Circular shapes are easy to obtain a mirror-like effect. The mirror-like effect is slightly worse at the corners and curved surfaces of complex shapes.

2. The bottom surface is easier to obtain a good mirror-like effect than the side surface. The deeper the cavity, the more difficult it is to obtain a mirror-like processing effect, especially on the side surface.

3. The larger the processing area, the more difficult it is to obtain a good mirror-like effect.

4. The mirror-like effect is poor at the opening and hollow parts of the cavity.

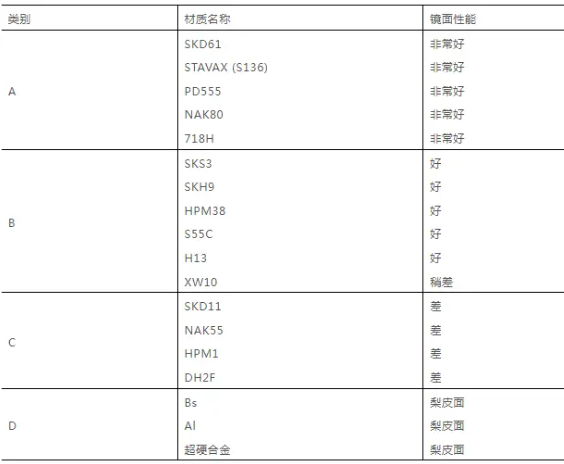

IV. Not all die steels can be mirror-like EDM processed

Some die steels can easily achieve a mirror-like effect in EDM, while some die steels cannot achieve a mirror-like effect no matter what. At the same time, the higher the hardness of the die steel, the better the mirror-like effect of EDM. Please refer to the table below for the performance of various materials and mirror-like processing.

V. Some requirements for electrodes in mirror-like EDM

The electrode material used for mirror-like EDM is generally purple copper or Lo copper, and Lo copper has less electrode wear. The selected copper material should be uniform in texture and have few impurities. Poor copper material is prone to large electrode wear and surface wrinkling during mirror-like processing, which should be highly valued. Although copper alloy electrodes can achieve extremely low electrode wear, the mirror-like effect is poor.

The electrodes used for mirror-like EDM must be finely polished and cannot have any tool marks or defects, otherwise these defects will be replicated to the processed surface of the workpiece, but it does not require the surface of the electrode to meet the mirror-like requirements.

The general scaling of mirror-like processing electrodes is 0.2~0.05 mm on one side, and the scaling of finishing electrodes is generally 0.1 mm on one side. It can be smaller when the processing area is smaller, smaller when the shape accuracy requirement is high, and larger when mixed powder processing is used. If the electrode scaling is too small, the processing speed will be greatly reduced.

Delicate mirror-like EDM requires multiple electrodes. This requires good consistency and high manufacturing accuracy of multiple electrodes, and high repeatability of electrode replacement, clamping, and positioning accuracy. Advanced technologies such as high-speed milling for electrode manufacturing, positioning methods using reference ball measurement, and using a quick clamping and positioning system for repeated positioning are generally used to meet the requirements.

VI. Control the machining allowance of mirror-like EDM

The EDM process is a process from rough machining to finishing. First, use a roughing electrode, under the condition of ensuring a certain processing quality (dimensional accuracy, shape accuracy, positional accuracy, surface roughness), use a larger discharge energy to remove a large amount of metal to shorten the processing time and improve processing efficiency; then replace the finishing electrode, and use a smaller discharge energy to complete the finishing. Whether it is rough machining or finishing, multiple discharge conditions will be used, and the current will also be from large to small, the bottom will be polished by depth feeding, and the side will be polished by reciprocating movement.

Each discharge condition must reserve a machining allowance for the subsequent condition. Reasonable machining allowance is the key to ensuring processing quality and efficiency. A larger machining allowance can ensure surface quality, but it will reduce the processing speed. A smaller machining allowance can achieve high efficiency, but the final mirror-like surface will have many pinholes or unevenness.

The ideal processing condition is that after the first condition is processed, the subsequent processing only polishes the surface unevenness formed by the first processing condition without removing new materials, that is, the material allowance of each condition is treated as zero. However, in mirror-like EDM, considering the ever-changing restrictive factors affecting the discharge condition, a little more machining allowance should be left for safety.

VII. Reasonable use of discharge parameters and processing control for mirror-like processing

Mirror-like EDM uses negative polarity processing. The selection of some non-main electrical parameters is also very important, and there are some differences from the selection of conventional processing. For example, the discharge time should be set longer, the lifting height should be shorter, and the lifting speed should not be too fast. The purpose of this setting is to maintain a stable low-energy electro-erosion process, because in mirror-like processing, not much electro-erosion products will be generated, and frequent lifting actions will interfere with the continuous and stable discharge.

The electro-erosion ability of the mirror-like processing electrode is very weak, and the processing process takes a long time. Since the dimensional changes during mirror-like processing are already very small and only play a polishing role, the processing can actually be ended as long as the required surface roughness is reached. Therefore, the timing processing function of the CNC EDM machine tool can be used to determine the processing time based on experience.

The processing method of the working fluid during mirror-like processing is also very important. Generally, immersion oil processing can be used to keep the working fluid in the processing area in a slightly circulating state. Do not use strong flushing, as strong flushing will interfere with the normal formation of micro-discharge.

Based on processing experience, as long as each stage of processing is handled properly, carbon deposits will generally not occur during mirror finishing. Therefore, machine downtime should be minimized during processing, especially avoiding the removal of the powder layer remaining on the workpiece surface.

8. Using mixed powder technology for large-area mirror finishing

Mixed powder EDM is a process method for improving the surface roughness of EDM. So-called mixed powder EDM refers to adding fine powder, such as silicon powder, aluminum powder, chromium powder, and related additives, to the working fluid to obtain a mirror finish on the processed surface.

Using mixed powder processing technology, under the same electrical parameter conditions, a faster processing speed (reducing finishing time by 20%-30%) and better surface roughness can be achieved compared to not using mixed powder processing technology. For large-area EDM, it has a significant improvement effect.

Mixed powder EDM requires the selection of suitable powder additives and a mixed powder working fluid circulation device, management of the concentration of powder additives, and the use of a diffusion device to eliminate concentration errors.

EDM technology is superior to milling. EDM is suitable for processing complex parts such as delicate small cavities, narrow slits, grooves, and corners.

Disclaimer : For the exchange and sharing of composite materials professional knowledge and market information only, not for any commercial purposes. If there are any copyright issues or questions about the content, please contact us immediately. We will deal with it promptly.

Related News