Detailed explanation of composite material molding process!

Release time:

2025-06-10

Composite material forming technology is the foundation and condition for the development of the composite material industry. With the expansion of the application fields of composite materials

Composite material molding processes are the foundation and conditions for the development of the composite materials industry. With the expansion of the application fields of composite materials, the composite materials industry has developed rapidly. Some molding processes have been perfected, and new molding methods continue to emerge. There are more than 20 molding methods for polymer-based composite materials, and they have been successfully used in industrial production, such as:

(1) Hand lay-up molding process - wet lay-up molding method;

(2) Spray molding process;

(3) Resin transfer molding technology (RTM technology);

(4) Bag molding (pressure bag molding);

(5) Vacuum bag molding;

(6) Autoclave molding technology;

(7) Hydraulic press molding technology;

(8) Thermal expansion molding technology;

(9) Sandwich structure molding technology;

(10) Molding material production process;

(11) ZMC molding material injection technology;

(12) Compression molding process;

(13) Laminate production technology;

(14) Roll-formed pipe molding technology;

(15) Fiber winding product molding technology;

(16) Continuous plate production process;

(17) Casting molding technology;

(18) Pultrusion process;

(19) Continuous winding pipe manufacturing process;

(20) Braided composite material manufacturing technology;

(21) Thermoplastic sheet molding compound manufacturing technology and cold press molding process;

(22) Injection molding process;

(23) Extrusion molding process;

(24) Centrifugal casting pipe molding process;

(25) Other molding technologies.

Depending on the resin matrix material used, the above methods are applicable to the production of thermosetting and thermoplastic composite materials, respectively. Some processes are applicable to both.

Characteristics of composite product molding processes: Compared with other material processing processes, composite material molding processes have the following characteristics:

(1) Material manufacturing and product molding are completed simultaneously. In general, the production process of composite materials is also the molding process of the product. The performance of the material should be designed according to the requirements of the product's use. Therefore, when selecting materials, designing the ratio, and determining the fiber lay-up and molding method, the physical and chemical properties, structural shape, and appearance quality requirements of the product must be met.

(2) Product molding is relatively simple. Generally, the resin matrix of thermosetting composite materials is a flowing liquid before molding, and the reinforcing material is soft fiber or fabric. Therefore, the number of processes and equipment required to produce composite material products using these materials is much simpler than other materials. For some products, only one set of molds is needed for production.

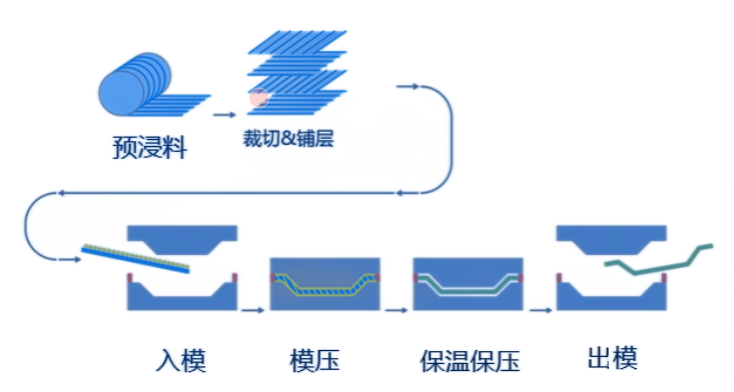

I. Compression Molding Process

Compression molding is an ancient yet vibrant molding method in the production of composite materials. It is a method of adding a certain amount of premix or prepreg into a metal die, and then curing it by heating and pressing.

Main advantages of compression molding process:

① High production efficiency, easy to achieve specialized and automated production;

② High product dimensional accuracy and good repeatability;

③ Smooth surface, no secondary modification required;

④ Can mold complex structures in one step;

⑤ Relatively low price due to mass production.

The disadvantages of compression molding lie in the complex mold manufacturing and large investment, coupled with the limitations of the press, making it suitable for mass production of small and medium-sized composite products. With the continuous improvement and development of metal processing technology, press manufacturing level, and synthetic resin process performance, the tonnage and table size of the press are continuously increasing, and the molding temperature and pressure of the molding material are also relatively reduced, so that the size of the compression molded products is gradually developing towards large-scale. Currently, large automotive parts, bathtubs, and integrated bathroom components can be produced.

Compression molding processes can be divided into the following types according to the physical state of the reinforcing material and the type of molding material:

① Fiber material compression molding method. This method involves putting premixed or prepreg fibrous molding materials into a metal mold and forming composite material products under certain temperature and pressure. This method is simple, easy to operate, and widely used. According to the specific operation, there are premixed material compression molding and prepreg compression molding methods.

② Scrap fabric compression molding method. This method involves cutting the scraps of glass fiber cloth or other fabrics (such as linen, organic fiber cloth, asbestos cloth, or cotton cloth) that have been soaked in resin solution into small pieces, and then forming composite material products in a metal mold under heating and pressure.

③ Fabric compression molding method. This method involves impregnating a two-dimensional or three-dimensional fabric woven into the required shape with a resin solution, and then placing it in a metal mold for heating and pressing to form a composite material product.

④ Laminate compression molding method. This method involves cutting glass fiber cloth or other fabrics that have been pre-impregnated with a resin solution into the required shape, and then forming composite material products in a metal mold by heating or pressing.

⑤ Winding compression molding method. This method involves providing a certain tension and temperature through a special winding machine for continuous fibers or fabrics (tapes) that have been pre-impregnated with a resin solution, winding them onto a core mold, and then placing them in a mold for heating and pressing to form composite material products.

⑥ Sheet molding compound (SMC) compression molding method. This method involves cutting SMC sheets according to the size, shape, and thickness requirements of the product, and then stacking multiple layers of sheets and placing them in a metal mold for heating and pressing to form the product.

⑦Preformed blank molding method First, preformed blanks with shapes and sizes similar to those of the chopped fiber products are placed in a metal mold, and then a prepared binder (resin mixture) is injected into the mold, and molding is performed under certain temperature and pressure.

There are many types of molded materials, which can be prepreg materials, premixed materials, or blanks. Currently used molded material varieties mainly include: prepreg tapes, fiber premixes, BMC, DMC, HMC, SMC, XMC, TMC and ZMC.

1. Raw materials

(1) Synthetic resin

The molding materials used for composite molding products require that the synthetic resin have: ① good wetting performance for the reinforcing material, so as to form a good bond at the interface between the synthetic resin and the reinforcing material; ② appropriate viscosity and good fluidity, which can be used under pressing conditions. Together with the reinforcing material, it evenly fills the entire mold cavity; ③ has a suitable curing speed under pressing conditions, and produces few or no by-products during the curing process, and has a small volume shrinkage rate; ④ can meet the specific performance requirements of the molded product. According to the above material selection requirements, commonly used synthetic resins include: unsaturated polyester resin, epoxy resin, phenolic resin, vinyl resin, furan resin, silicone resin, polybutadiene resin, allyl ester, melamine resin, polyimide resin, etc. In order to achieve specific performance indicators for molded products, after selecting the resin type and grade, corresponding auxiliary materials, fillers and pigments should also be selected.

(2) Reinforcing material

Commonly used reinforcing materials in molding materials mainly include glass fiber chopped strands, un-twisted roving, twisted roving, continuous glass fiber bundles, glass fiber cloth, glass fiber felt, etc. A small amount of special products also use asbestos felt, asbestos fabrics (cloth) and asbestos paper, as well as high-silica fiber, carbon fiber, organic fiber (such as aramid fiber, nylon fiber, etc.) and natural fiber (such as linen, cotton, boiled cloth, unboiled cloth, etc.). Sometimes, two or more types of fibers are mixed as reinforcing materials.

(3) Auxiliary materials

Generally includes curing agents (initiators), accelerators, diluents, surface treatments, low-shrinkage additives, release agents, colorants (pigments) and fillers.

2. Preparation of molding materials

Taking glass fiber (or glass cloth) impregnated resin molding materials as an example, the production process can be divided into two types: premixing method and prepreg method.

(1) Premixing method First, the glass fiber is cut into short cut fibers of 30~50mm, and after being fluffed, it is fully kneaded with the resin glue liquid in a kneader until the resin completely wets the glass fiber, and then dried (air-dried) to an appropriate viscosity. Its characteristics are that the fibers are loose and non-directional, the production volume is large, and the specific volume of the molding material produced by this method is large and the fluidity is good, but the fiber strength loss is relatively large during the preparation process.

(2) Prepreg method The fiber prepreg method is to make continuous glass fiber (or cloth) into bundles through impregnation, drying, and cutting. Its characteristics are that the fibers are bundled and relatively tight, and the fiber strength loss is relatively small during the preparation of the molding material, but the fluidity of the molding material and the compatibility between the material bundles are slightly worse.

SMC, BMC, HMC, XMC, TMC and ZMC production technology

Sheet Molding Compound (SMC) is a type of sheet molding material made by impregnating fibers or chopped fiber felts with resin paste and covering both sides with polyethylene film, belonging to the prepreg felt material range. It is one of the widely used molding materials in the world.

SMC is a sheet molding material formed by impregnating short-cut fiber roving or glass fiber felt with a resin paste mixed with unsaturated polyester resin, thickener, initiator, crosslinking agent, low-shrinkage additive, filler, internal release agent and colorant, and covering both sides with polyethylene or polypropylene film. SMC, as a rapidly developing new type of molding material, has many characteristics:

① Good reproducibility, not affected by operators and external conditions;

② Convenient operation and handling;

③ Clean and hygienic operating environment, improving working conditions;

④ Good fluidity, can be molded into irregularly shaped products;

⑤ The molding process does not require high temperature and pressure, and the variable range is large, which can significantly reduce equipment and mold costs;

⑥ Fiber length 40~50mm, good uniformity, suitable for pressing large thin-walled products with little change in cross-section;

⑦ The surface finish of the obtained product is high, and after using low-shrinkage additives, the surface quality is even better;

⑧ High production efficiency, short molding cycle, easy to achieve fully automatic mechanized operation, and relatively low production cost.

As a new type of material, SMC has developed a series of new varieties according to different specific uses and requirements, such as BMC, TMC, HNC, XMC, etc.

① Bulk Molding Compound (BMC) Its composition is very similar to SMC, and it is an improved premixed bulk molding material that can be used for molding and extrusion molding. The difference between the two lies only in the material form and manufacturing process. BMC has a lower fiber content and shorter fiber length, about 6~18mm, and a larger filler content, so the strength of BMC products is lower than that of SMC products. BMC is more suitable for pressing small products, while SMC is suitable for large thin-walled products.

② Thick Molding Compound (TMC) Its composition and manufacturing are similar to SMC, with a thickness of up to 50mm. Because TMC is thick, glass fibers can be randomly distributed, improving the wettability of the resin to the glass fibers. In addition, this material can also be used for injection and transfer molding.

③High-strength molding compound (HMC) and high-strength sheet molding compound (XMC) are mainly used in the manufacturing of automotive parts. HMC contains little or no filler and uses short-cut glass fiber with a fiber content of around 65%. The glass fiber is directionally distributed, resulting in excellent flowability and molding surface. The strength of its products is approximately three times that of SMC products. XMC uses directional continuous fibers with a fiber content of 70% to 80% and contains no filler.

④ZMC ZMC is a molding technology. The three letters ZMC have no actual meaning but encompass the meanings of molding compound, injection molding machinery, and molds. ZMC products maintain high strength indicators while also possessing excellent appearance and high production efficiency. Combining the advantages of SMC and BMC, it has achieved rapid development.

1. Raw materials of SMC

The raw materials of SMC are composed of three major categories: synthetic resin, reinforcing material, and auxiliary material.

(1) Synthetic resin The synthetic resin is an unsaturated polyester resin. Different unsaturated resins have a direct impact on the thickening effect of the resin paste, process characteristics, product performance, shrinkage rate, and surface state. SMC has the following requirements for unsaturated polyester resin:

①Low viscosity and good glass fiber wetting performance;

②Sufficient reactivity with the thickener to meet thickening requirements;

③Rapid curing, short production cycle, and high efficiency;

④The cured product has sufficient hot strength for easy hot demolding of the product;

⑤The cured product has sufficient toughness to prevent cracking when the product undergoes certain deformations;

⑥Low shrinkage rate.

(2) Reinforcing material The reinforcing material is short-cut glass fiber coarse yarn or raw silk. In unsaturated polyester resin molding compounds, the reinforcing material currently used for SMC is only short-cut glass fiber felt, while there are more reinforcing materials used for premixes, including short-cut glass fiber, asbestos fiber, hemp, and various other organic fibers. In SMC, the glass fiber content can be adjusted between 5% and 50%.

(3) Auxiliary materials Auxiliary materials include curing agents (initiators), surface treatment agents, thickeners, low-shrinkage additives, release agents, colorants, fillers, and cross-linking agents.

2. SMC preparation process

The SMC production process mainly includes resin paste preparation, pasting operation, fiber cutting sedimentation and impregnation, resin thickening, etc. The process flow chart is as follows:

(1) Preparation and pasting operation of resin paste

There are two methods for resin paste preparation: batch method and continuous method. The batch method procedure is as follows:

①Pour unsaturated polyester resin and styrene into the mixing tank and stir evenly;

②Pour the initiator into the mixing tank and mix it with the resin and styrene;

③Add thickener and release agent under stirring;

④Add filler and low-shrinkage additive under low-speed stirring;

⑤Stop stirring when the components listed in the formula are dispersed and let it stand for later use. The continuous method is to divide the resin paste in the SMC formula into two parts: thickener, release agent, part of the filler and styrene as one part, and the rest of the components as another part. After separate metering and mixing, they are sent to the corresponding storage containers set up in the SMC unit. When needed, they are metered by pipeline metering pumps and then enter the static mixer. After mixing evenly, they are transported to the pasting area of the SMC unit and then coated onto the polyethylene film.

(2) Impregnation and compaction The lower carrier film coated with resin paste enters the short-cut glass fiber sedimentation chamber under the traction of the unit. The cut short-cut glass fiber settles evenly on the resin paste. After reaching the required sedimentation amount, it leaves the sedimentation chamber with the transmission device and overlaps with the upper carrier film coated with resin paste. Then, it enters a series of staggered roller arrays. Under the action of tension and rollers, the lower and upper carrier films tightly press the resin paste and short-cut glass fiber together. After repeated multiple times, the short-cut glass fiber is impregnated with resin and the air bubbles are expelled, forming a dense and uniform continuous SMC sheet.

According to the length of the molding cycle, composite molding materials are generally divided into two types: rapid molding process and slow molding process. The rapid molding process is suitable for pressing small, thin-walled composite products, while the slow molding process is suitable for pressing large, thick-walled composite products.

III. Thermoplastic composite molding process

Thermoplastic composites are a general term for various thermoplastic resins reinforced with glass fiber, carbon fiber, aramid fiber, etc. They are called FRTP (Fiber Reinforced Thermo Plastics) abroad. Due to the different types of thermoplastic resins and reinforcing materials, their production processes and the properties of the resulting composite materials vary greatly.

From the perspective of production process, plastic composites are divided into two categories: short fiber reinforced composites and continuous fiber reinforced composites:

Short fiber reinforced composites

①Injection molding process; ②Extrusion molding process; ③Centrifugal molding process. (2) Continuous fiber reinforced and long fiber reinforced composites ①Prepreg molding; ②Sheet molding compound stamping; ③Sheet molding compound vacuum forming; ④Prepreg yarn winding; ⑤Pultrusion.

The special properties of thermoplastic composites are as follows:

(1) Low Density, High Strength: The density of thermoplastic composites is 1.1~1.6 g/cm3, only 1/5~1/7 that of steel, and 1/3~1/4 lighter than thermosetting fiberglass. It can achieve higher mechanical strength with less unit mass. Generally speaking, whether it is general-purpose plastics or engineering plastics, reinforcement with glass fiber will achieve a higher enhancement effect, improving strength and application level.

(2) High Degree of Design Freedom: The physical, chemical, and mechanical properties of thermoplastic composites are designed by reasonably selecting raw material types, ratios, processing methods, fiber content, and lamination methods. Because thermoplastic composites have many more types of matrix materials than thermosetting composites, the degree of freedom in material selection design is much greater.

(3) Thermal Properties: The general use temperature of plastics is 50~100℃. After being reinforced with glass fiber, it can be increased to over 100℃. The heat deflection temperature of nylon 6 is 65℃, which can be increased to 190℃ after being reinforced with 30% glass fiber. The heat resistance of polyetheretherketone resin reaches 220℃, and the use temperature can be increased to 310℃ after being reinforced with 30% glass fiber. Thermosetting composites cannot achieve such high heat resistance. The coefficient of linear expansion of thermoplastic composites is 1/4~1/2 lower than that of unreinforced plastics, which can reduce the shrinkage rate during the product molding process and improve the dimensional accuracy of the product. Its thermal conductivity is 0.3~0.36 W/(㎡·K), similar to that of thermosetting composites.

(4) Chemical Corrosion Resistance: The chemical corrosion resistance of composites is mainly determined by the properties of the matrix material. There are many types of thermoplastic resins, each with its own corrosion resistance characteristics. Therefore, the matrix resin can be optimized according to the use environment and medium conditions of the composite material, and generally meets the requirements of use. The water resistance of thermoplastic composites is superior to that of thermosetting composites.

(5) Electrical Properties: General thermoplastic composites have good dielectric properties, do not reflect radio waves, and have good microwave transmission performance. Because the water absorption rate of thermoplastic composites is lower than that of thermosetting fiberglass, their electrical properties are superior to the latter. After adding conductive materials to thermoplastic composites, their conductivity can be improved, and static electricity can be prevented.

(6) Waste Recyclability: Thermoplastic composites can be repeatedly processed and molded, and waste and scraps can be recycled without causing environmental pollution.

Due to the many superior properties of thermoplastic composites compared to thermosetting fiberglass, their application fields are very wide. Based on the analysis of foreign applications, thermoplastic composites are mainly used in vehicle manufacturing, electromechanical industries, chemical corrosion protection, and construction engineering.

1. Injection Molding Process

Injection molding is the main production method for thermoplastic composites, with a long history and wide application. Its advantages are: short molding cycle, low energy consumption, high product precision, complex products with inserts can be molded at one time, one mold can produce several products, and high production efficiency. The disadvantages are that it cannot produce fiber-reinforced composite products and has high requirements for mold quality. According to the current level of technological development, the largest product of injection molding is 5 kg, and the smallest is 1 g. This method is mainly used to produce various mechanical parts, building products, appliance housings, electrical materials, vehicle parts, etc.

2. Extrusion Molding Process

Extrusion molding is one of the widely used processes in the production of thermoplastic composite products. Its main characteristics are continuous production process, high production efficiency, simple equipment, and easy-to-master technology. Extrusion molding is mainly used to produce pipes, rods, plates, and profiles. Glass fiber-reinforced plastic pipes and profiles for doors and windows have a large market in China. The process flow of extrusion-molded composite products is as follows:

3. Winding Molding Process

The principle of winding molding and the winding machine equipment for thermoplastic composites are the same as those for thermosetting glass. The difference is that the reinforcing material for winding products of thermoplastic composites is not fiberglass coarse yarn, but prepreg yarn impregnated with (thermoplastic resin). Therefore, a prepreg yarn preheating device and a heating and pressing roller need to be added to the winding machine. During winding molding, the prepreg yarn is first heated to its softening point, then the contact point with the core mold is heated, and pressure is applied by a pressure roller to fuse them into a whole.

4. Pultrusion Molding of Thermoplastic Composites

The pultrusion molding process of thermoplastic composites is basically similar to that of thermosetting fiberglass. As long as the impregnation method before entering the mold is modified, the equipment for producing thermosetting fiberglass can be used. There are two types of reinforcing materials for producing pultruded thermoplastic composite products: one is prepreg yarn or prepreg tape, and the other is unimpregnated fiber or fiber tape.

5. Welding Bonding Method

This method uses the weldability of thermoplastic composites to produce composite plates. The method is as follows: First, a layer of prepreg (generally 500 mm wide) is laid on the workbench. When laying the second layer of prepreg, the welding device of the pressure roller is started, and the prepreg is sent under the pressure roller. The welding device heats and melts the upper and lower layers of prepreg simultaneously within a few seconds. As the machine moves forward, the prepreg is bonded together under the pressure (0.3 MPa) of the pressure roller. By repeating this process, plates of any thickness can be produced.

6. Stamping Molding Process of Thermoplastic Sheet Molding Compounds

The stamping molding of thermoplastic sheet molding compounds is different from the pressing molding of thermosetting SMC. It requires preheating the blank before placing it in the mold for pressing and molding.

7. Joining Technology of Thermoplastic Composites

There are many methods for joining thermoplastic composites, as listed below:

① Riveting: The rivets used for riveting thermoplastic composites are generally made of continuous fiber-reinforced thermoplastic plastics, preferably pultruded rods. During construction, the rivets are preheated to a temperature at which they can be pressure-deformed. The rivets and hole diameters should be tightly fitted, neither too large nor too small. Metal bolts can also be used. The advantages of riveting are good impact resistance, no electrochemical corrosion, and low cost.

②Welding: Thermoplastic composite materials are welded by heating the surfaces to be joined to a molten state, then overlapping and pressing them together to form a single unit. The welding principle of composite materials is similar to that of plastics, but it is important to note that the fiber reinforcement effect at the weld should not be significantly reduced.

③Butt Welding of Pipes: There are two methods for butt welding thermoplastic composite pipes: direct butt welding and reinforced butt welding. The advantages of this connection method are simple process, on-site construction, no need for machining of the pipes, high connection strength, and low breakage rate. The disadvantages are high cost and strict process requirements, requiring precise dimensional matching.

④Wrap Welding: A prepreg tape is manually or mechanically wrapped along the weld seam, and a flame gun is used to heat and melt the contact points, bonding them to the parts to be joined. When selecting the prepreg tape, attention should be paid to the fiber direction and content. This method is relatively practical, and the materials to be joined can retain better properties, but uneven heating may occur.

⑤Ultrasonic Welding of Thin Plates: This method uses ultrasonic waves to heat and weld the parts to be joined, generally achieving high connection strength.

IV. Other Forming Processes

Other forming processes for polymer matrix composites mainly refer to centrifugal casting, casting, elastomer resin molding (ERM), and reinforced reaction injection molding (RRIM).

1. Centrifugal Casting Process

In the production of composite products, centrifugal casting is mainly used to manufacture pipes (underground pipes). Resin, glass fiber, and fillers are added to a rotating mold cavity in a certain proportion and method. The centrifugal force generated by high-speed rotation compresses and consolidates the materials, forming them into shape.

Centrifugal glass fiber reinforced plastic pipes are divided into pressure pipes and non-pressure pipes, with operating pressures ranging from 0 to 18 MPa. The pipe diameter generally ranges from φ400 to φ2500 mm, with large diameters reaching 5 m. Pipes with diameters of φ1200 mm or more are more cost-effective. The length of centrifugal pipes is 2-12 m, generally 6 m.

Centrifugal glass fiber reinforced plastic pipes have many advantages. Compared with ordinary glass fiber reinforced plastic pipes and concrete pipes, they have high strength, light weight, corrosion resistance, wear resistance (5-10 times that of asbestos cement pipes), energy saving, durability (more than 50 years), and low overall project cost, especially for large-diameter pipes. Compared with winding and sanding glass fiber reinforced plastic pipes, their main features are high rigidity, low cost, and the pipe wall can be designed with a multi-layer structure according to its function. The centrifugal pipe manufacturing process has stable quality and low raw material consumption, and its overall cost is lower than that of steel pipes. Centrifugal glass fiber reinforced plastic pipes can be buried up to 15 m deep and can withstand vacuum and external pressure. The disadvantage is that the inner surface is not smooth enough, and the hydraulic characteristics are relatively poor.

Centrifugal glass fiber reinforced plastic pipes have broad application prospects. Their main applications include: water supply and drainage pipelines, oilfield injection pipes, sewage pipes, chemical corrosion-resistant pipes, etc.

(1) Raw Materials

The raw materials for producing centrifugal pipes include resin, glass fiber, and fillers (powder and granular fillers).

Resin: Unsaturated polyester resin is widely used. The resin grade and curing agent can be selected according to the operating conditions and process requirements.

Reinforcing Material: The main material is glass fiber and its products. Glass fiber products include continuous fiber felt, mesh cloth, and unidirectional cloth. When manufacturing products with irregular cross-sections, glass fiber can be first made into preforms and then placed in the mold.

Filler: The function of the filler is to increase the rigidity and thickness of the product and reduce the cost. The type of filler should be selected according to the requirements of use, generally quartz sand, quartz powder, and diabase powder.

(2) Process Flow

The process flow of centrifugal pipe manufacturing is as follows:

The material feeding method for centrifugal pipe manufacturing is different from that of winding molding. The material feeding system integrates the feeding devices for resin, fiber, and filler onto a reciprocating trolley.

(3) Mold

The molds for producing glass fiber reinforced plastic pipes using the centrifugal method are mainly steel molds. Molds are divided into integral and assembled types: molds for pipes smaller than φ800 mm use integral molds, while molds for pipes larger than φ800 mm can use assembled molds.

The mold design should ensure sufficient strength and rigidity to prevent deformation during rotation and vibration. The mold consists of a pipe body, end caps, and support rings. The pipe body is made of rolled and welded steel plates. For small-diameter pipes, seamless steel pipes can be used. The end caps increase the strength of the mold ends and prevent material leakage. The support rings support the mold, transmit the rotational force, and allow the mold to rotate at high speed in the centrifuge. The inner surface of the mold pipe body should be flat and smooth, and generally requires fine machining and polishing to ensure smooth demolding.

2. Casting Process

Casting is mainly used to produce fiber-reinforced composite products, such as artificial marble, buttons, embedded plant and animal specimens, handicrafts, anchor rod fixatives, and decorative panels.

Casting is relatively simple, but skilled operation is required to produce high-quality products.

(1) Button Production Process

Buttons cast with polyester resin have high hardness, good gloss, wear resistance, heat resistance, dry cleaning resistance, a wide variety of colors, and low prices. They have basically replaced acrylic buttons in China and abroad, accounting for more than 80% of the button market.

The raw materials for producing buttons are mainly unsaturated polyester resin, curing agent (methyl ethyl ketone peroxide is used as the initiator), and auxiliary materials (including color paste, pearlescent powder, thixotropic agent, etc.).

Polyester buttons are produced using a centrifugal casting rod casting method. First, plates or rods are made, then cut into buttons, and then processed through heat treatment, surface scraping, bottom scraping, slotting, drilling, and polishing to produce finished buttons.

(2) Artificial Stone Production Process

Artificial stone is made from unsaturated polyester resin and fillers. Due to the different fillers used, artificial stone is divided into artificial marble, artificial agate, artificial granite, and polyester concrete.

The raw materials for producing artificial stone are unsaturated polyester resin, fillers, and pigments:

①Resin The resin used to produce artificial stone is divided into surface layers and structural layers. The surface decorative layer resin requires low shrinkage, good toughness and hardness, heat resistance, wear resistance, and water resistance, and it should also be easy to color. Neodecanoic acid phthalate resin is used for artificial stone, while neodecanoic acid isophthalate resin is used for sanitary ware production. The curing system commonly uses methyl ethyl ketone peroxide and cobalt naphthenate solution.

②Fillers There are many fillers used in the production of artificial stone. The fillers for producing artificial marble are marble powder, quartz powder, dolomite powder, calcium carbonate powder, etc. The fillers for producing artificial granite use graded granular materials, with different colors of granular materials used for different types of granite. The fillers for producing artificial agate must have a certain degree of transparency, generally using aluminum hydroxide or aluminum oxide.

③Pigments Various pigments are needed to produce artificial stone. For example, when producing artificial marble or artificial agate bathtubs, heat-resistant and water-resistant color pastes should be selected. When manufacturing decorative panels and crafts, lightfast, water-resistant, and durable pigments should be selected.

The mold materials used to produce artificial marble and granite slabs include fiberglass, stainless steel, plastic, and glass. The templates for producing artificial stone slabs require a smooth, glossy surface, sufficient strength and rigidity, and the ability to withstand thermal stress, handling loads, and collisions during the production process.

3. Elastic Reservoir Resin Molding Technology

Elastic Reservoir Molding (ERM) is a new technology that emerged in Europe and America in the 1980s. It uses flexible materials (open-cell polyurethane foam) as the core material and infiltrates resin paste. This foam impregnated with resin paste remains in the middle of the finished ERM material. The foam reduces the density of the ERM product and increases its impact strength and rigidity, so it can be called a compression-molded laminated structure product.

Like SMC, ERM belongs to the category of compression-molded sheet molding compounds. However, due to its laminated structure, ERM has advantages over SMC:

Lightweight: ERM is more than 30% lighter than products made with felt and SMC; (2) The specific stiffness of ERM products is superior to that of SMC, aluminum, and steel products; (3) High impact strength: Under the condition of the same reinforcement material content, the impact strength of ERM is much higher than that of SMC; (4) High physical and mechanical properties: Under the condition of the same reinforcement material content, the physical and mechanical properties of ERM products are superior to those of SMC products; (5) Low investment cost: The ERM molding unit is simpler than the SMC unit, and the molding pressure of ERM products is about 10 times lower than that of SMC products. Therefore, low-tonnage presses and low-strength material molds can be used to produce ERM products, thus reducing investment.

The ERM product production process is divided into two processes: ERM manufacturing and ERM product molding:

(1) ERM Production Process The raw materials for ERM production are open-cell polyurethane foam, various fiber products (such as short-cut felt, continuous fiber felt, and knitted felt made of glass fiber, carbon fiber, and aramid fiber), and various thermosetting resins. The production process is as follows: First, the prepared resin paste is impregnated into the open-cell polyurethane foam on the ERM unit. The resin paste is applied to the foam using a coating device, and the resin paste is squeezed into the pores of the foam using a pressure roller. Then, two layers of foam are combined, and glass fiber felt or other fiber products are laid on the upper and lower surfaces to form an ERM laminated material, which is cut into suitable sizes for compression molding or storage.

(2) ERM Product Production Process Compared with other thermosetting molding compounds (fiberglass cloth or felt prepreg, SMC, etc.), ERM product production requires curing under hot pressing conditions, but the molding pressure is much smaller than that of SMC, approximately 1/10 of the SMC molding pressure, at 0.5~0.7MPa.

ERM technology is currently mainly used in the automotive industry and lightweight building composite materials industry. Due to the characteristics of its laminated structure, ERM is suitable for producing large-scale structural components, various lightweight panels, mobile homes, radar domes, doors, etc. In the automotive industry, products include luggage trailers, covers, instrument panels, bumpers, doors, and floor panels.

4. Reinforced Reaction Injection Molding Technology

Reinforced Reaction Injection Molding (RRIM) is a molding method that uses high-pressure impact to mix two monomer materials and short-fiber reinforcing materials, and injects them into a mold cavity to form a product through a rapid curing reaction. If no reinforcing material is used, it is called Reaction Injection Molding (RIM). When continuous fiber reinforcement is used, it is called Structural Reaction Injection Molding (SRIM).

RRIM raw materials are divided into two categories: resin systems and reinforcing materials.

(1) Resin System The resin used for RRIM should meet the following requirements: ①It should be composed of two or more monomers; ②The monomers should remain stable at room temperature; ③The viscosity should be appropriate and easy to pump; ④After mixing the monomers, they should cure quickly; ⑤The curing reaction should not produce by-products. Polyurethane resin, unsaturated polyester resin, and epoxy resin are commonly used.

(2) Reinforcing Materials Commonly used reinforcing materials include glass fiber powder, glass fiber, and glass microspheres. In order to increase the bonding strength between the reinforcing material and the resin, the above reinforcing materials are all surface-treated with a coupling agent.

Process characteristics of RRIM:

①High degree of freedom in product design, allowing for the production of large-sized components;

②Low molding pressure (0.35~0.7MPa), no molding stress during reaction molding, and small amount of heat generation in the mold;

③Low shrinkage rate of the product, good dimensional stability, due to the addition of a large amount of fillers and reinforcing materials, reducing resin curing shrinkage;

④Simple embedded part process for products;

⑤ The surface quality of the product is good, and glass powder and glass beads can improve the wear resistance and heat resistance of the product;

⑥ Simple production equipment, low mold cost, short molding cycle, and low product production cost. The major user of RRIM products is the automotive industry, which can be used for car bumpers and dashboards. High-strength RRIM products can be used as structural materials and load-bearing materials for automobiles. Due to its short molding cycle and designable performance, it is used in electrical insulation engineering, anti-corrosion engineering, and mechanical instrumentation industries, replacing engineering plastics and polymer alloys.

Related News