The purpose and method of making a radome

Release time:

2025-05-27

The radome protects the antenna system from rain, wind, ice, snow, sand, dust, and solar radiation, ensuring stable and reliable performance, reducing wear, corrosion, and aging, and extending its service life.

I. Purpose of Using a Radome

1. Protecting the antenna system Radomes can prevent wind, rain, ice, snow, sand, and dust, and solar radiation from affecting the antenna system, making the antenna system work more stably and reliably. At the same time, it reduces wear, corrosion, and aging of the antenna system, extending its service life.

2. Reduce wind resistance and wind load: Reduce the driving power of the rotating antenna, reduce the weight of the mechanical structure and reduce the inertia, and improve the natural frequency.

3. Improve equipment efficiency: Relevant equipment and personnel can work inside the radome without being affected by the external environment, improving equipment efficiency and improving working conditions for operators.

4. Solve problems in harsh environments: For high-speed aircraft, radomes can solve problems caused by high temperatures, aerodynamic loads, and other loads on the antenna, ensuring the normal operation of the antenna under harsh conditions.

However, The radome is an obstacle in front of the antenna, which will absorb and reflect the antenna's radiated waves, change the antenna's free-space energy distribution, and affect the antenna's electrical performance to a certain extent.

The reason is: ① Reflection of the radome wall and diffraction of uneven parts will cause the electrical axis of the antenna main lobe to shift, resulting in aiming errors; ② Absorption and reflection of high-frequency energy by the radome will cause transmission loss, thereby affecting the antenna gain (increasing the system noise temperature during reception); ③ Antenna lobe distortion caused by the radome changes the width of the antenna main lobe, increases the depth of the zero point, and increases the sidelobe level; Secondly, Radomes increase engineering costs. Antennas on aircraft generally have radomes, while ground radomes are not yet widely used.

II. Classification of Radomes

1. From the perspective of use, they are divided into two major categories: aviation type and ground (including shipborne) type.

2. Electrically, according to the incident angle of the antenna radiation wave, it is divided into a vertical incidence radome and a large incident angle radome. The angle between the radiation wave ray and the normal of the radome wall is the incident angle. An incident angle of less than 30° is called a vertical incidence radome. The antenna scans to any position in the radome, and the range of change in the incident angle is relatively large (from 0 to 75 or more), which is called a large incident angle radome. The latter has significantly lower electrical performance than the former.

3. According to the cross-sectional shape of the radome wall, radomes are divided into three types: uniform single-wall structure, sandwich structure, and space frame structure.

4. According to the forming method of the radome, ground radomes are divided into two types: inflatable radomes and rigid radomes.

Although radomes protect antennas, side effects are often unavoidable. For example, the reflection of electromagnetic waves emitted by the antenna on the surface of the radome and the absorption in the dielectric layer of the radome cause power loss and reduce the operating distance of the electronic system; the refraction phenomenon in the dielectric layer causes angle measurement errors. In some cases, this error is fatal; multiple reflections in the dielectric layer, similar to multipath effects, will cause an increase in nearby clutter. Therefore, in the design, it is required that after adding the radome, the specified limit indicators cannot be exceeded.

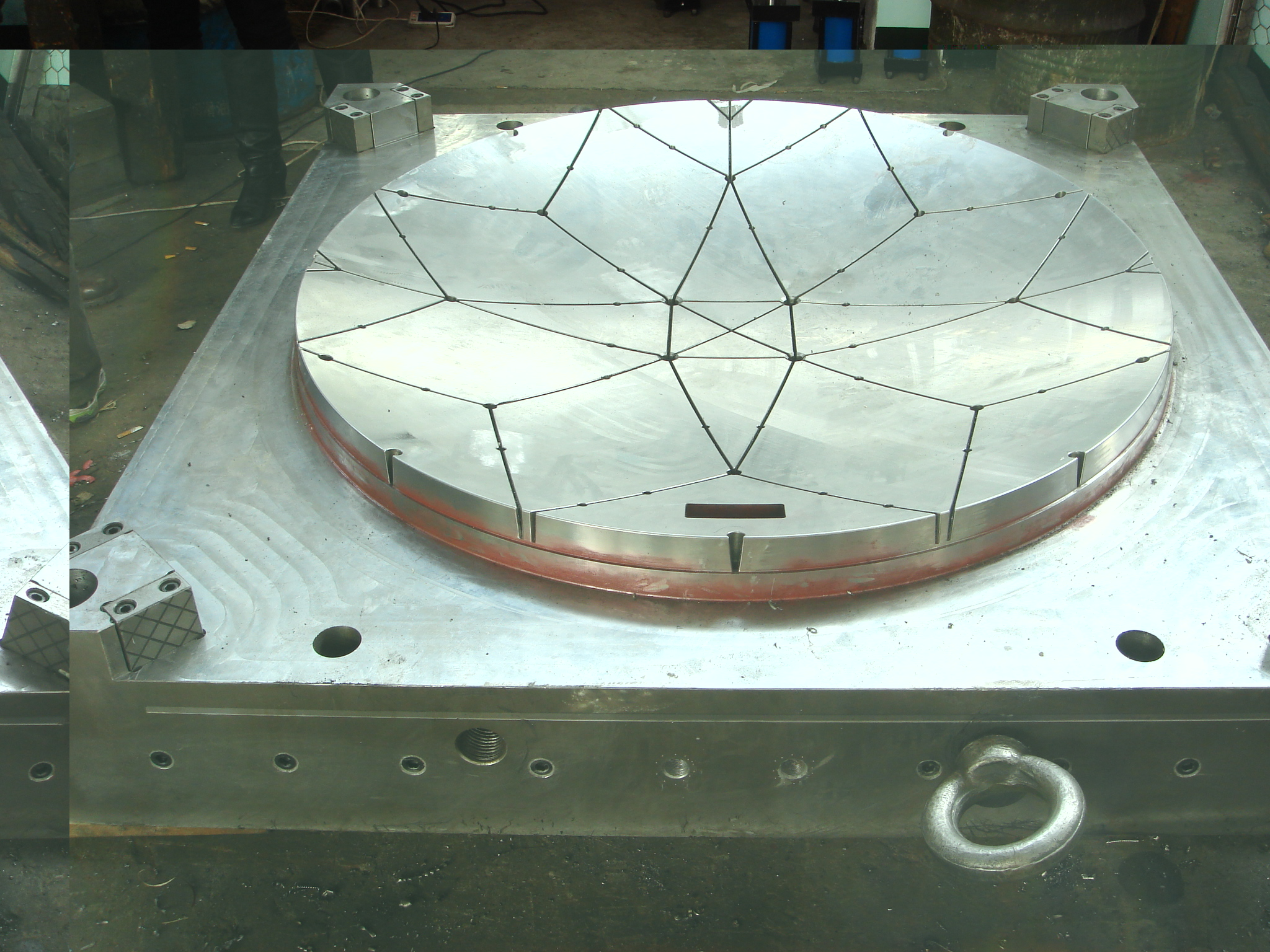

So, what are the methods for making radomes? In the traditional view, molds seem to be tools for making radomes.

III. Methods for Making Radomes

1. The advantages of mold-making radomes are high production efficiency and high dimensional accuracy. Through mold forming, a large number of radomes with consistent shapes and accurate dimensions can be quickly produced.

2. Hand forming: For small batches or customized radomes, hand forming is a cost-effective option. Through steps such as manual shaping, polishing, and painting, radomes that meet the requirements can be produced. Although hand forming is less efficient, it is less expensive and can produce unique shapes and designs.

3. 3D printing technology: With the development of 3D printing technology, more and more fields have begun to try applying this technology. For radome manufacturing, 3D printing technology can achieve rapid prototyping and small-batch production. Through 3D printing technology, radomes with complex shapes can be produced, and the production cycle is short and the cost is low.

4. Composite material molding: Composite materials have the advantages of being lightweight, high-strength, and corrosion-resistant, so they are widely used in radome manufacturing. By selecting suitable composite materials and molding processes, radomes with excellent performance can be produced. Composite material molding methods are diverse, and suitable processes can be selected according to specific needs.

IV. Choosing a Suitable Manufacturing Method

When choosing a radome manufacturing method, it is necessary to comprehensively consider the specific needs and material characteristics. For mass production and radomes with high dimensional accuracy requirements, mold making may be a better choice. For small batches, customized products, or radomes that need frequent design changes, hand forming, 3D printing, or composite material molding may be more suitable. In addition, factors such as manufacturing cost and production cycle should also be considered to ensure that the produced radome meets the requirements and is cost-effective.

Related News